Face Editor

Contents

- 1 Face Editor overview

- 2 Viewing the face

- 3 Coordinate System

- 4 Drawing shapes

- 4.1 Selecting the drawing mode

- 4.2 Drawing circles

- 4.3 Drawing ellipses

- 4.4 Drawing rectangles (and squares)

- 4.5 Drawing custom paths

- 4.6 Drawing lines

- 4.7 Drawing arcs

- 4.8 Adding text

- 4.9 Adding images

- 5 Measuring distances

- 6 Using the grid

- 7 Managing object properties

- 8 Adding cutouts

- 9 Adding hardware

- 10 Manipulating objects

- 11 Printing one or more faces on paper for review

- 12 Exporting and importing face templates

- 13 Face Editor preferences

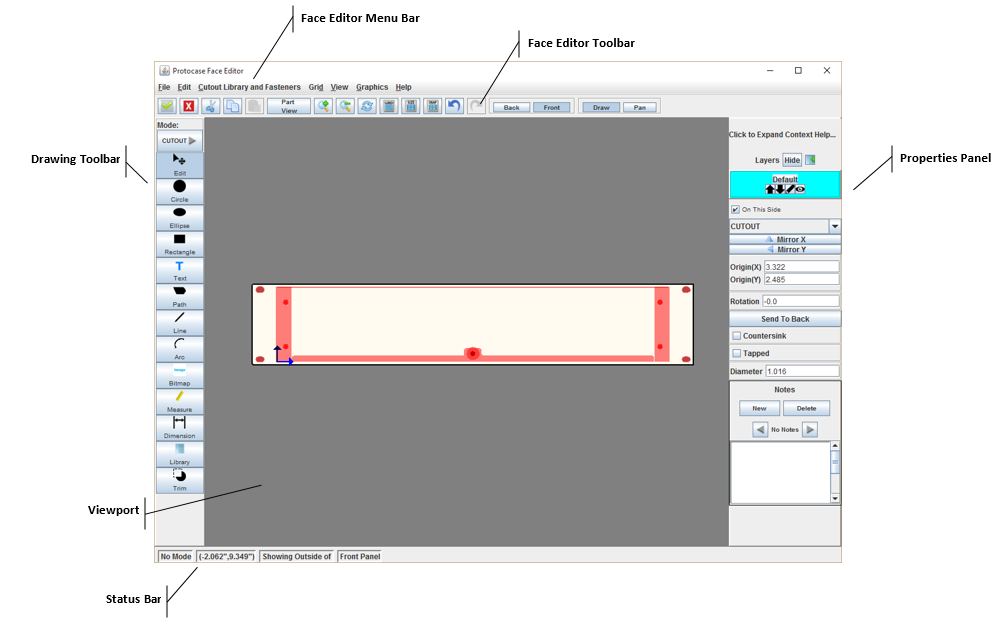

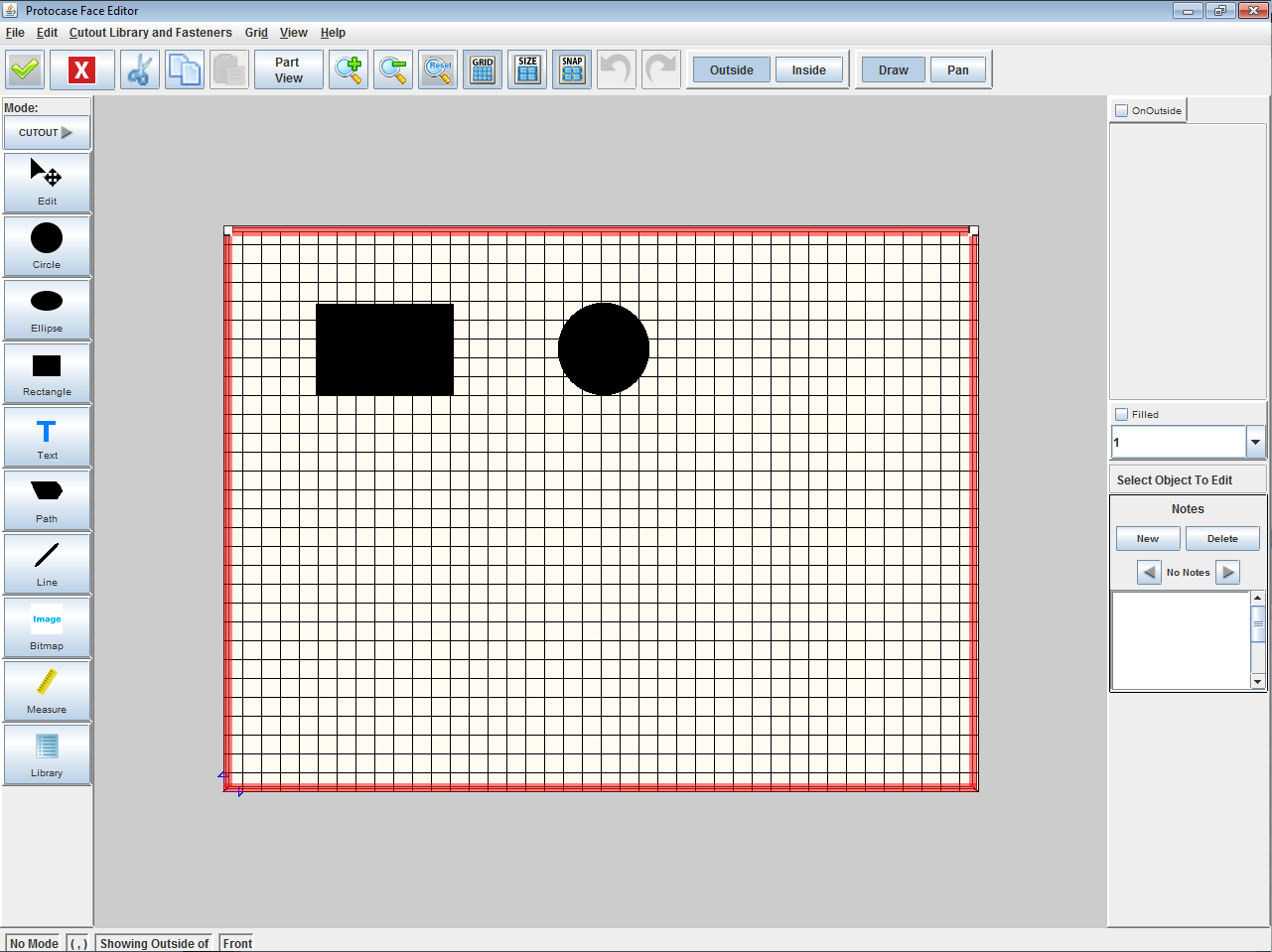

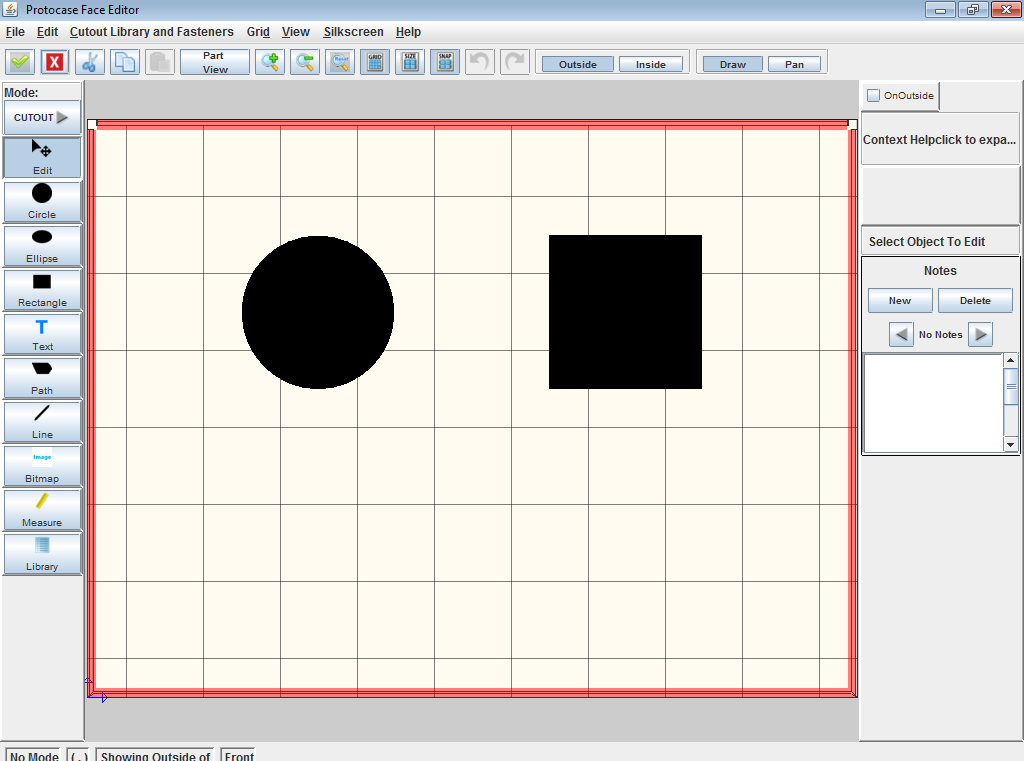

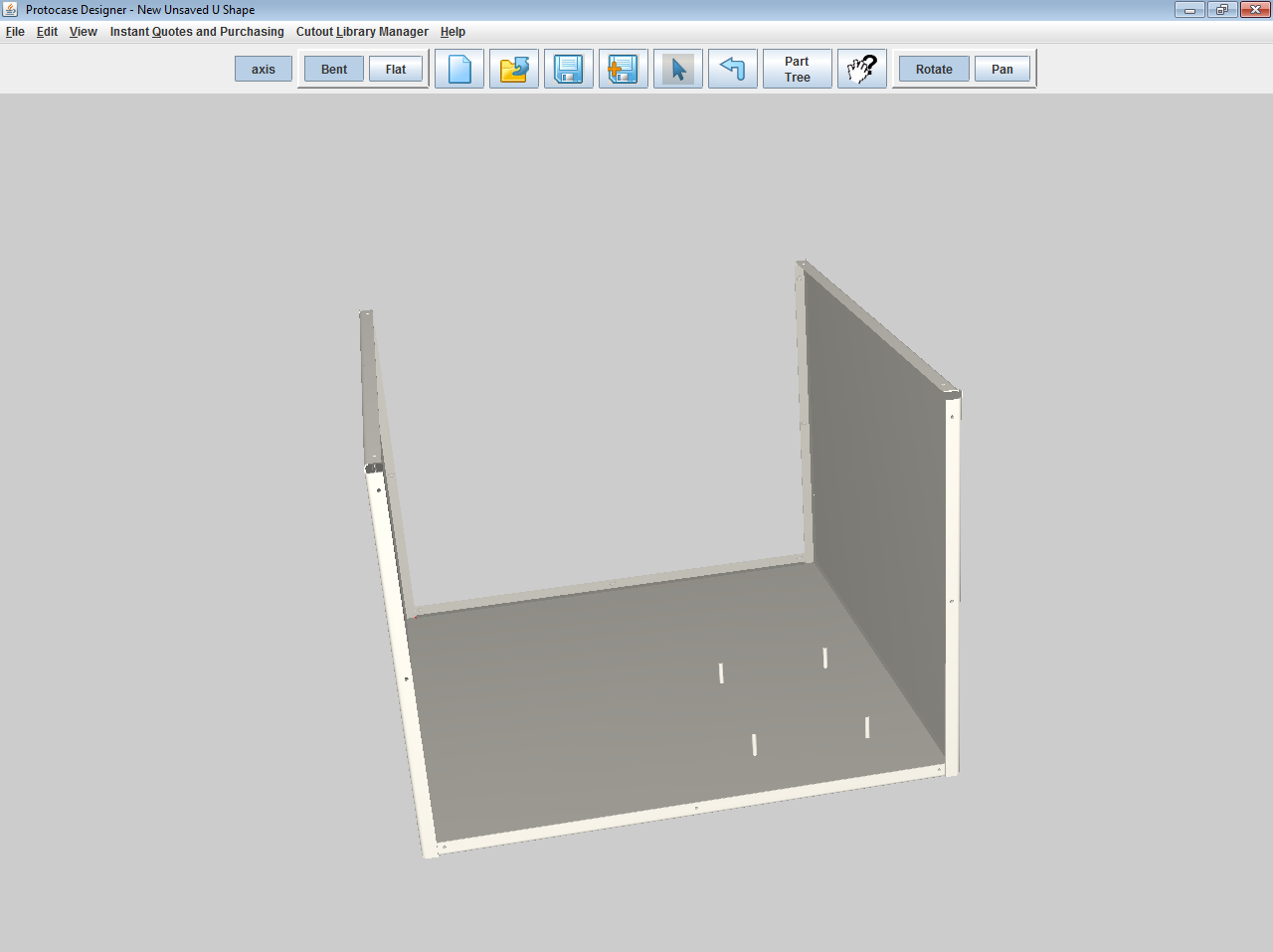

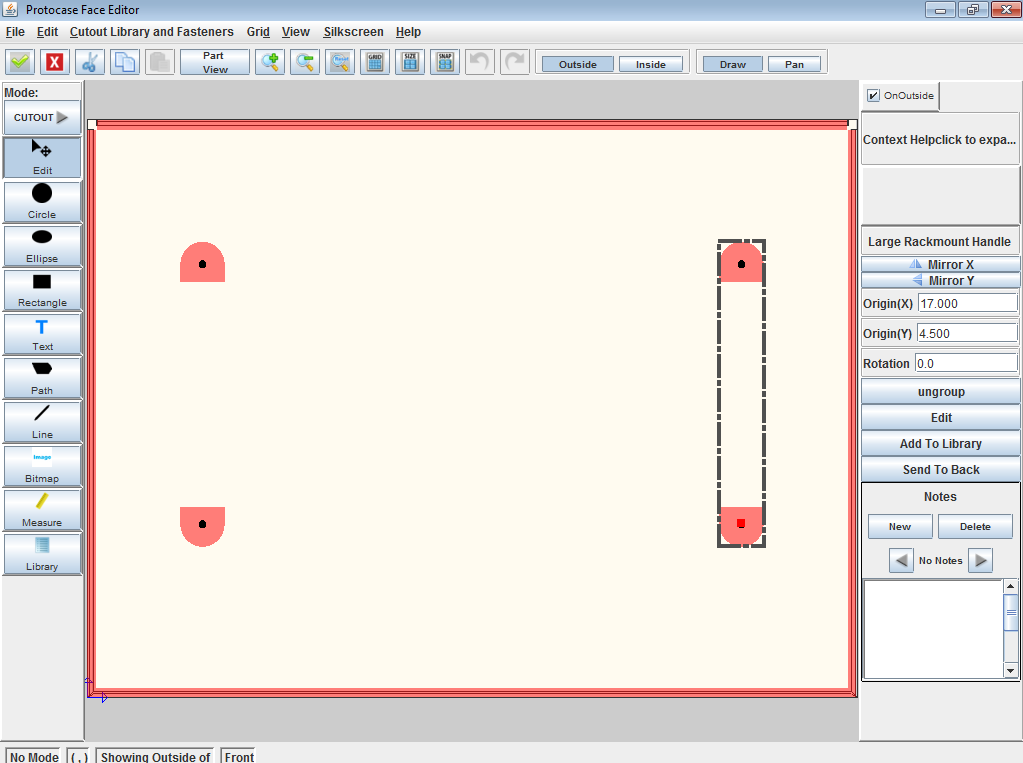

Face Editor overview

The Face Editor allows you to customize the faces of your enclosure using standard editing tools for creating cutouts, silkscreens, exclusions zones, and construction lines.

- Face Editor Menu Bar

- Contains File, Edit, Cutout Library and Fasterners, Grid, View, Graphics, and Help menus.

- Face Editor Toolbar

- Contains common commands such as Cut, Copy, Paste, Undo, Redo, Zoom, and Grid-related commands.

- Drawing panel

- Contains tools to draw shapes, add text, and add images to the face.

- Viewport

- Working area that shows a 2D view of your enclosure face.

- Status bar

- Displays the currently selected view, X- and Y coordinates of the pointer, side of face showing (outside or inside), and the name of the face.

- Properties panel

- Displays Help and properties that can be changed for the selected object.

Viewing the face

Panning

To Pan the face, do one of the following.

Method 1

- In the viewport, click the wheel button and drag to pan the model to the desired location.

Method 2

- On the Standard Toolbar, click Pan.

- In the viewport, left-click and drag to pan the model to the desired location.

Method 3

- Press and hold the Alt key.

- In the viewport, right-click and drag to pan the model to the desired location.

Zooming

To Zoom in or out, do one of the following:

Method 1

- Rotate the wheel button forward or backward.

Method 2

- On the Standard Toolbar (or on the View menu), click Zoom In or Zoom Out.

- Click within the viewport to incrementally zoom the model in or out.

Method 3

- On the Standard Toolbar, click Zoom In.

- Drag a diagonal selection within the viewport to zoom in to a desired area of the model.

Note: The model moves toward the mouse pointer when zooming out and away from the mouse pointer when zooming in.

Resetting the view

The Reset View command displays the face in the centre of the viewport at its original zoom level.

Do one of the following:

Method 1

- On the Standard Toolbar, click Reset View.

Method 2

- On the View menu, click Reset Zoom to display the model in its original orientation.

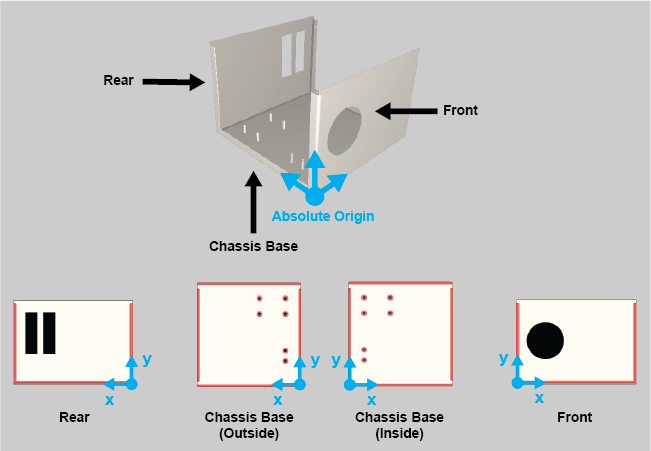

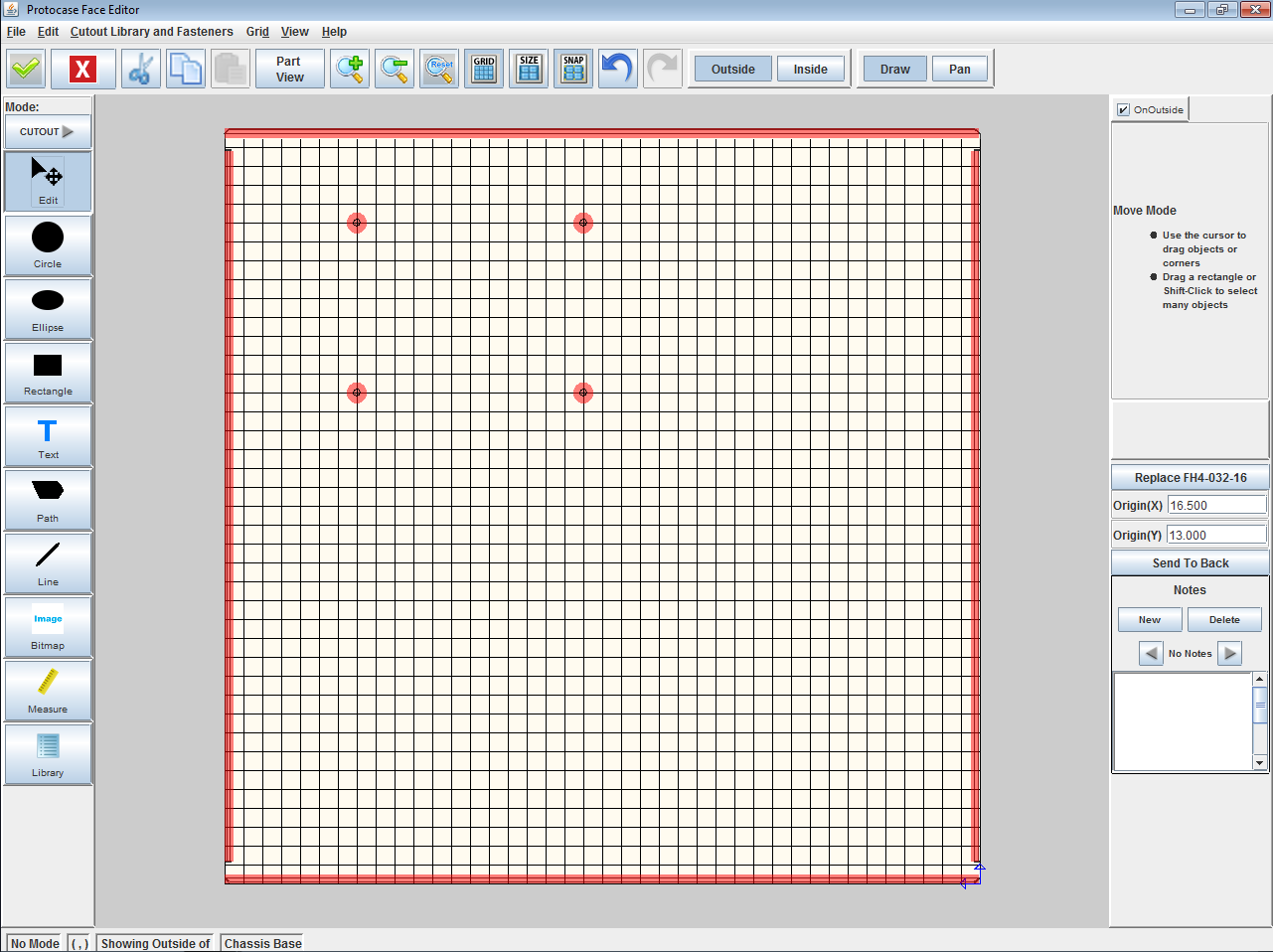

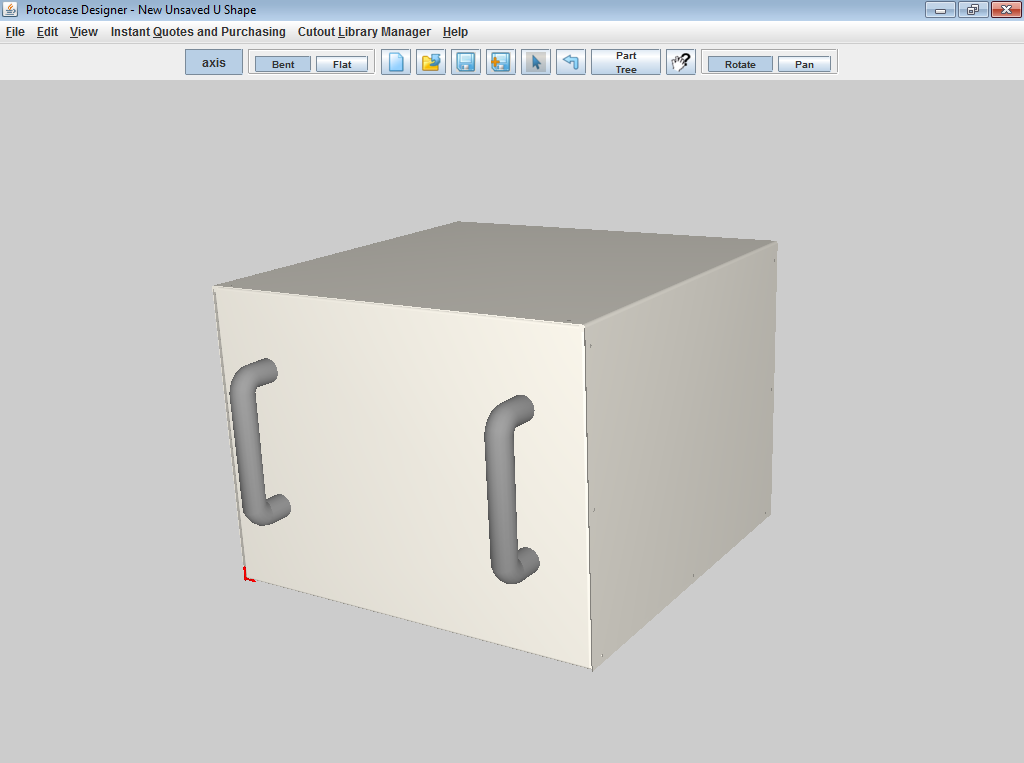

Coordinate System

The origin in the Face Editor is located at the absolute coordinate system of the model. The x- and y-coordinates for each face are referenced from the absolute origin and always increase moving away from the origin. The figure below shows examples of the coordinate system for several faces on a U-Shape enclosure.

Choosing the Units of Measure

You can set the default unit of measure.

- Choose Preferences from the Edit menu.

- Click the down-arrow for Display Units.

- Select the unit of measure (INCHES, CM, or MM).

- Click OK.

Drawing shapes

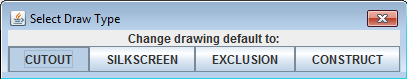

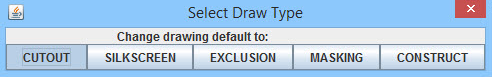

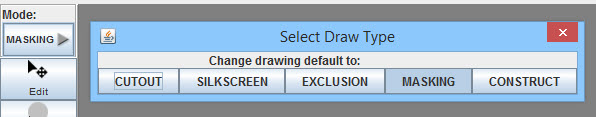

Selecting the drawing mode

Selecting the drawing mode determines the type of objects created: Cutout, Silkscreen, Exclusion, Construct, and, if the enclosure metal is anything other than Cold Rolled Steel, Masking.

- On the Drawing Toolbar, click the button under the "Mode" label; by default, the button is set to Cutout.

- Click the button for the drawing type you want to set as the default. The selected button changes color to indicate the current default drawing mode.

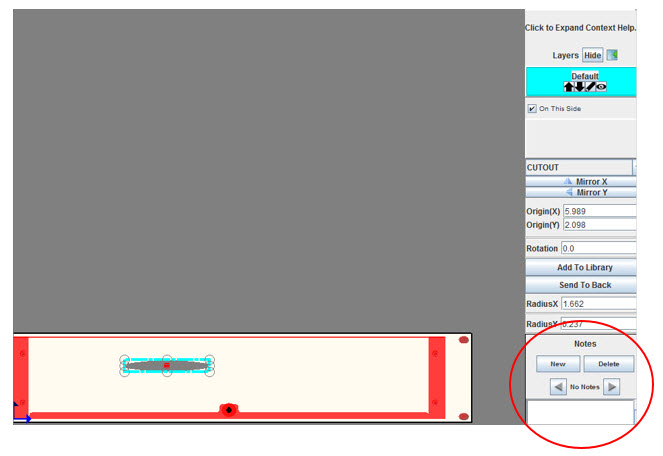

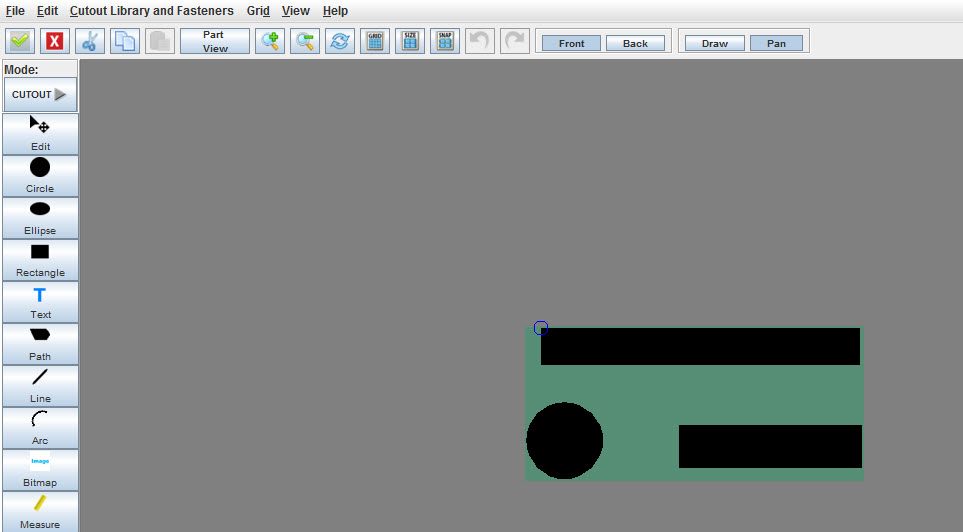

Using the Cutout drawing mode

The Cutout drawing mode allows you to draw shapes on your enclosure for accommodating connectors, switches, ports, etc. You can also draw custom shapes to create cutout logos and images.

See Also:

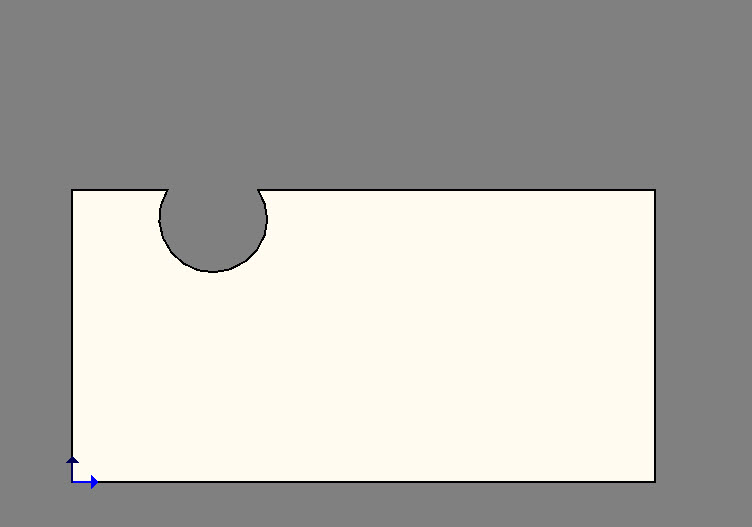

Editing cutouts: Cutting into the perimeter of a face

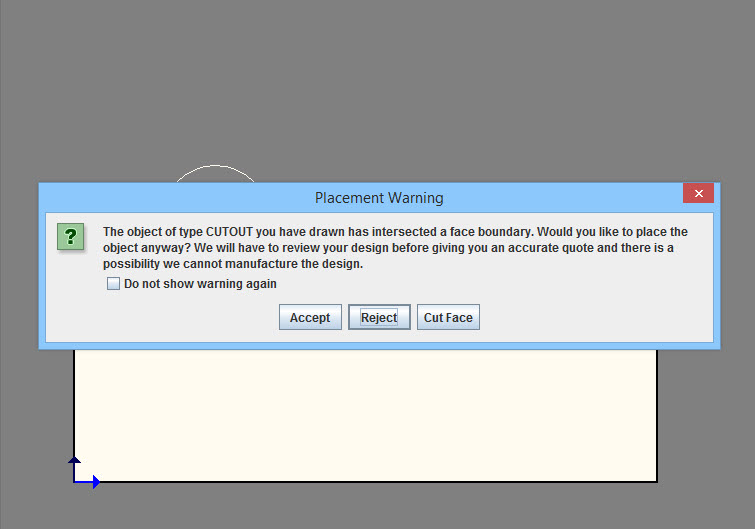

You can create cutouts in any edge of a face, including where two faces meet.

- In the Face Editor, make sure that the mode is set to CUTOUT.

- Place or draw a cutout so that it intersects a boundary of the face.

- A placement warning is displayed, with three options:

- Accept this placement

- Reject this placement

- Cut Face using this placement

- Note A placement warning is not an error message. You can cut into a boundary, which is always displayed in black. You cannot cut into an exclusion zone, which is always displayed in red.

- A placement warning is displayed, with three options:

- Click the Cut Face button.

See Also:

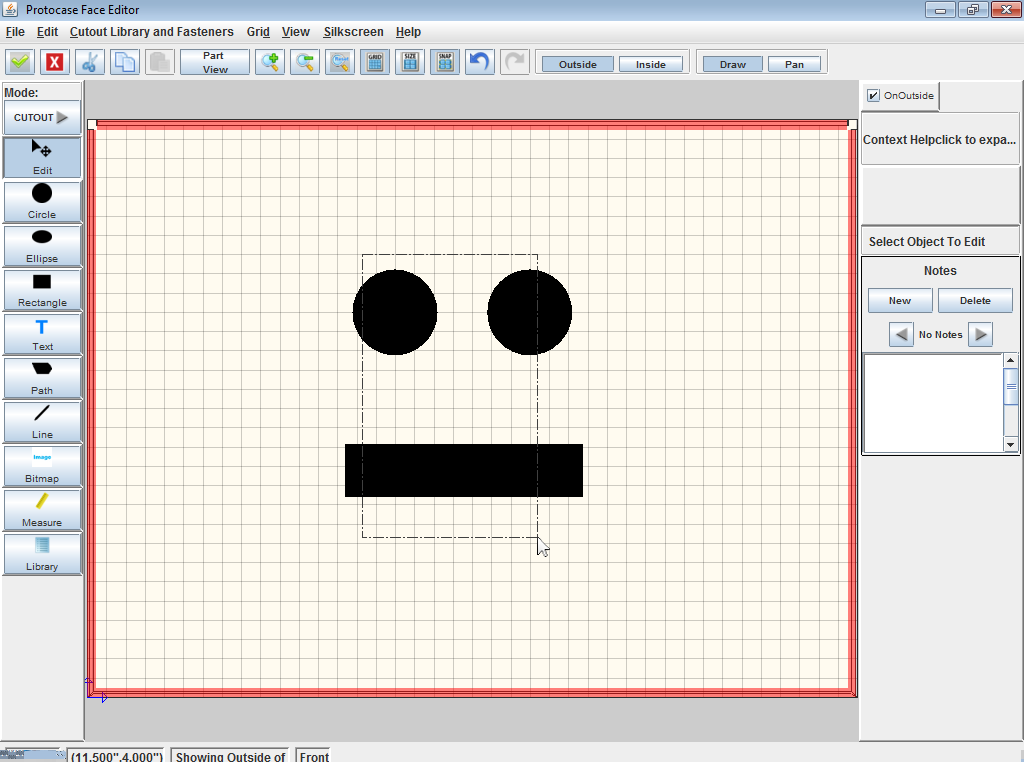

Using the Silkscreen drawing mode

The Silkscreen drawing mode lets you add images and text to the enclosure, for silkscreening or for direct digital printing. Silkscreening is limited to specific colors; direct digital printing can print any number of colors, including gradients, with precise rendering. Note that you cannot apply both silkscreening and digital printing to the same face. For details on both silkscreening and digital printing, please see About Silkscreening.

Adding silkscreening or direct digital printing

Important! When using digital printing, please note:

- You cannot use digital printing on metal if the color is "None"; it does not stick to bare metal so the enclosure must have a color.

- You cannot use digital printing on aluminum or stainless steel with a grained finish.

- The printed area must be no more than 6" high, 10" wide, and 24" long.

- The face and all its attachments must be entirely flat. Nothing can stick up above the surface.

- The inside of the face cannot be printed.

These limitations do not apply to silkscreening.

For more information on Direct Digital Printing including limitations, finishes, fonts, colors, printing over cutouts, and image placement, see

[Direct Digital Printing].

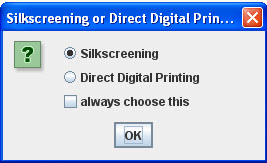

To choose silkscreening or digital printing

- Load the face you want to edit.

- In the Face Editor, either click the Text button, or change the Mode to "Silkscreen".

- Select either the Silkscreening or Direct Digital Printing radio button.

- To make your choice the default printing method for all subsequent faces, select the always choose this check box.

- Note: You can also specify the default printing method in the Graphics Type field in Preferences. Whichever method you choose, the default will be used for all new faces. If other faces are using a different method and you want to change them, edit each face and choose Silkscreen > Convert to Direct Digital Printing or Convert to Silkscreen.

- Click OK.

- Add text and/or images to the face.

To change from one printing method to the other

- In the Face Editor, select the face that you want to change.

- Choose the Convert... command from the Silkscreen menu.

- Note: There is no separate menu for digital printing; the Silkscreen menu is used for both. If the face is silkscreened, the Convert to Direct Digital Printing command is listed in the menu. If the face is digital print, the Convert to Silkscreen' command is listed in the menu.

- If you choose Convert to Silkscreen, a confirmation window opens. Click Yes to confirm the conversion to stock silkscreen colors.

See Also:

- Adding silkscreening to a face using a different graphics editor

- Tell me about silkscreening and digital printing

Using the Exclusion drawing mode

The Exclusion drawing mode allows you to add shapes to your enclosure to mark areas where other objects cannot be added.

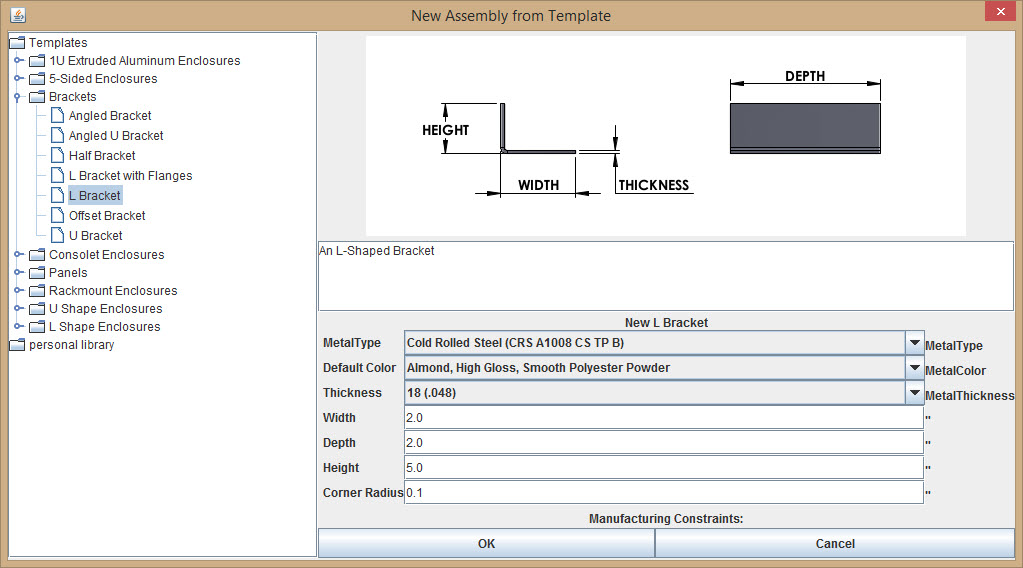

Using the Masking drawing mode

Masking is the process in which Protocase puts tape over a spot before painting it, so that it stays bare. This is usually done to make a bare spot for an electrical ground. In Designer, the Masking drawing mode lets you specify masking on any metal except cold rolled steel, which would rust. (The Masking button is not displayed if the material does not allow it.)

- Select the enclosure template you want to use.

- In the New Assembly from Template dialog, change MetalType to any type other than Cold Rolled Steel. (Aluminum is the most common metal that is masked.)

- Select the face you want to add masking to.

- In the Mode menu, click the Masking button.

- Choose a shape (preferably Rectangle) and draw the spot(s) you want masked.

Using the Construct drawing mode

The Construct drawing mode lets you draw shapes on your enclosure for use as reference when creating cutouts, silkscreen or exclusion zones, as well as when placing hardware.

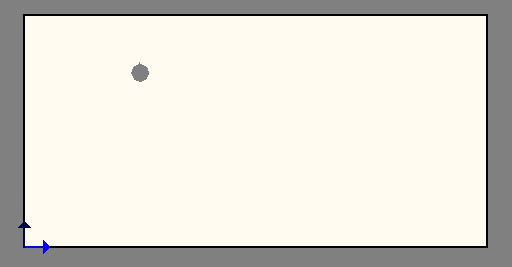

Drawing circles

- On the Drawing Toolbar, select the Circle tool.

- Click to place the centre of the circle.

- Drag to set the corner of the bounding box.

- Continue drawing circles and select the Edit tool

when you are done.

when you are done.

Drawing ellipses

- On the Drawing Toolbar, select the Ellipse tool.

- Click to place the centre of the ellipse.

- Drag to set the corner of the bounding box.

- When you are finished drawing ellipses, press <Esc> or click the Edit tool

.

.

Drawing rectangles (and squares)

- On the Drawing Toolbar, select the Rectangle tool.

- Click to place the corner of the rectangle.

- Drag to set the corner of the bounding box. To draw a square, use the grid to restrict the bounding box to a square, or change the Width and Height (in the Properties panel) to be equal.

- When you are finished drawing, press <Esc> or click the Edit tool

.

.

Drawing custom paths

Available in all drawing modes.

- On the Drawing toolbar, click the Path tool

.

. - Click on the face to place each point of the path.

- Click the first point again to finish the path and fill the shape.

Creating an arc using the Path tool

- On the Drawing toolbar, click the Path tool.

- Click on the face to place the starting point of the arc (and, if you want to start the path with straight lines, additional points for each line segment).

- Click the arc button in the Properties panel, or press <a>.

- Click on the face to place the end of the arc.

- The arc is drawn, but is not yet locked. Note: The arc might not be displayed until you move the pointer.

- Drag the arc to change its size, then click to lock the arc size.

- The end point is the start of the next arc or line in the path. You can continue to place arcs, or change to lines (by clicking line on the Properties panel or by pressing <A>).

- If you are creating a cutout, close the path, either by ending a line or arc on the first point in the path, or by clicking Close Path in the Properties panel. Until the path is closed, it will not be displayed in the 3D View. (If you are creating a graphical object, it does not need to be closed, and will be displayed correctly in the 3D View.)

Path editing: Using the Trim and Merge tools to create cutouts

The Trim and Merge tools provide quick ways to create paths for cutouts. The Merge tool lets you create an outline (path) by merging multiple shapes. The Trim tool lets you delete lines in intersecting shapes to create the path you want.

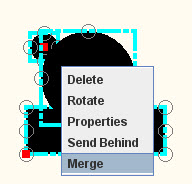

To merge two or more objects

- Place two or more objects on a face, each overlapping at least part of one other object.

- Click the Edit button and select all the objects you want to merge. (If you select an object by accident, you can remove it by holding down the Shift key and clicking the object you accidentally selected.)

- Right-click within the selection and choose Merge from the popup menu.

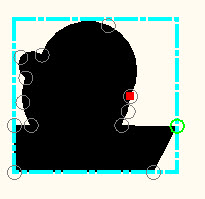

To edit a merged object If you select a merged object, each node in what is now a single object can be dragged to further change the object shape. In this example, the selected node (colored red) is being dragged up and to the right.

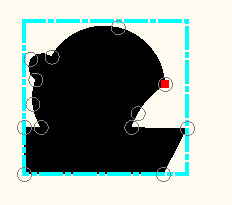

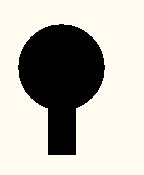

To trim two or more objects In this example, a key slot is created with the Trim tool.

- Place a circle on the face.

- Add a rectangle to the bottom of the face, overlapping it.

- Click the Edit button and select both objects.

- Click the Trim button.

- Use the eraser to eliminate the lines you do not want.

- When you are done, press the Esc key on your keyboard, or click any other button in the Drawing toolbar, to exit the Trim mode. Important! If you click the Accept and Close button now, the trims will not be saved.

See Also:

Solving problems with merging objects

If objects being merged are very close to matching in size but are not perfectly matching, Designer can encounter redrawing issues that result in the cutouts disappearing and reappearing in the design. To fix such problems while retaining inexact matches, trim all the segments that are causing the problems, as described in this topic. (To ensure that objects match exactly, use the grid or specify positions as described in Creating custom vents.) Note that although both topics use vent slots as an example, the same general procedures apply to any merged cutout.

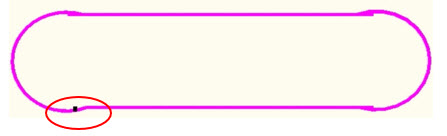

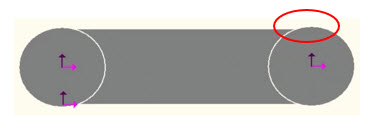

In this example, a vent slot was made by joining two circles and a rectangle. After the rectangle was drawn, the circles were added visually to each end of the rectangle, nearly perfectly the same size as the rectangle but extending just slightly beyond its top and bottom:

If you then merge them and click <Esc>, because the circle diameters are not exactly the same as the rectangle height, the image completely disappears from the 3D View, but are still in the Face Editor view.

If you experience this problem but would like the slot to remain as designed, follow these steps to fix it. If you would like the slot to be the same size all the way across, delete the problem slot and draw a new one using either method given in creating vent slots.

- Click the Edit tool and select the two circles and the rectangle.

- Use the Trim tool to remove all the intersections of the circles with the rectangles that you do not want. Zoom in enough to see the tiny segments remaining, and remove them as well.

- When completed, click the <Esc> key or the Accept and Close button, and the objects are merged correctly.

Drawing lines

- On the Drawing Toolbar, click the Line tool.

- Click and hold down the mouse button to start the line.

- Drag to set the end of the line.

- When you are finished drawing lines, click the Edit tool

or press <Esc>.

or press <Esc>.

Drawing arcs

- On the Drawing Toolbar, click the Arc tool.

- Click and hold down the mouse button to start the line that will describe the arc.

- Drag the line, and release the mouse button at the end of the arc.

- Move the mouse to a point on the arc and drag to resize it; when it is the size you wish, click the mouse to complete the arc.

- When you are finished drawing arcs, click the Edit tool

or press <Esc>.

or press <Esc>.

Adding text

- On the Drawing toolbar, click the Text button.

- Click on the face and begin typing.

- Note: After placing one piece of text, even if you press the <Enter> key, you are still in text mode; if you click elsewere on the face anywhere and type, you will enter more text at that new location. This allows you to enter multiple text blocks at a time.

- When you are finished adding text blocks, click the Edit tool

or press <Esc>.

or press <Esc>. - Using the Properties panel, you can now change the Rotation, Font, Font Size, and Font Style. You can also edit the Text. For details, see Managing object properties.

Adding images

- On the Drawing Toolbar, click the Bitmap button.

- Click the face where you want to place the image.

- The Open dialog is displayed.

- Enter the file name, then click Open.

- Note: The file name might not be listed in the Open dialog. Navigate to the folder for the file, then enter the file name.

Exporting bitmaps

You can export a bitmap that has been imported to a face.

- In the Face Editor, click the Edit button in the Drawing panel, then click the bitmap you want to export.

- Click the Save To File button in the Properties panel.

- The Save dialog opens.

- Choose the folder, enter the file name, and click Save. The bitmap is exported to a .PNG file.

Measuring distances

To determine the distance between two points on objects or anywhere on a face:

- On the Drawing toolbar, click the Measure button.

- On the face, click the start point (the object or location that is to be the reference point), then click the end point (the object or location that is to be placed in reference to the starting point).

- You can continue measuring distances. When done, click the Edit tool

or press <Esc>.

or press <Esc>.

See Also:

- Using the Measure tool to move an object a specific distance from another object

- Using the Measure tool to specify both distance and alignment between objects

- Dimensions: Displaying measurements for review

Using the Measure tool to move an object a specific distance from another object

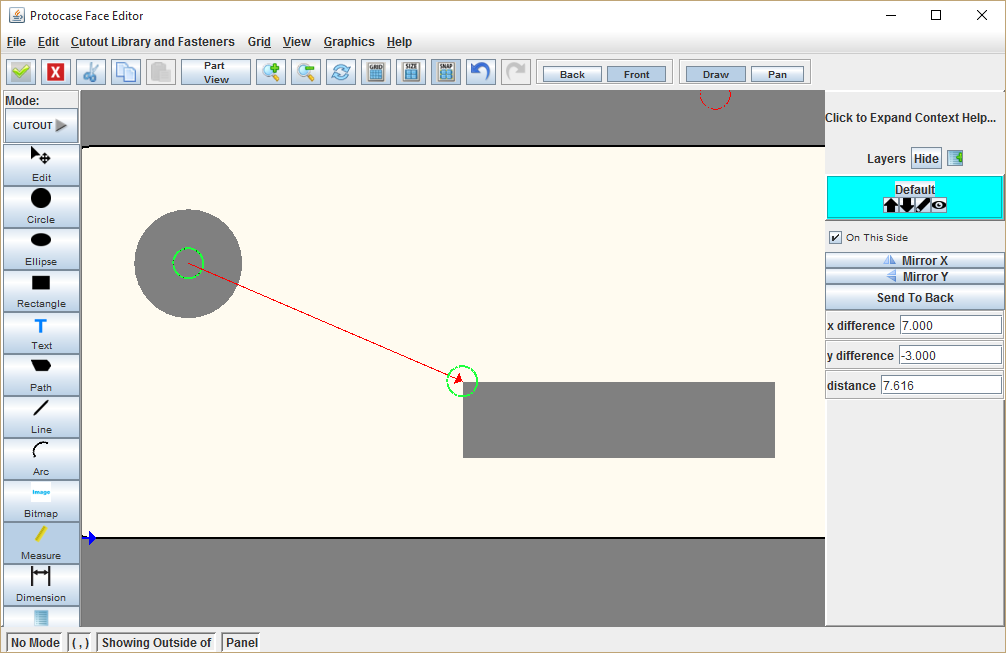

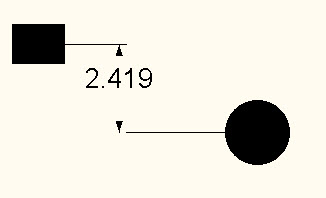

You can use the Measure tool to move an object a specific distance from another object. This example shows how to move the centre of a circle cutout 5 inches to the right and 3 inches below the bottom right corner of a rectangle cutout.

- On the Drawing toolbar in the Face Editor, click the Measure button.

- Click the bottom right corner of the rectangle cutout.

- Click the centre of the circle cutout.

- Enter "5" in x difference and "-3" in y difference.

See Also

- Measuring distances

- Using the Measure tool to specify both distance and alignment between objects

- Dimensions: Displaying measurements for review

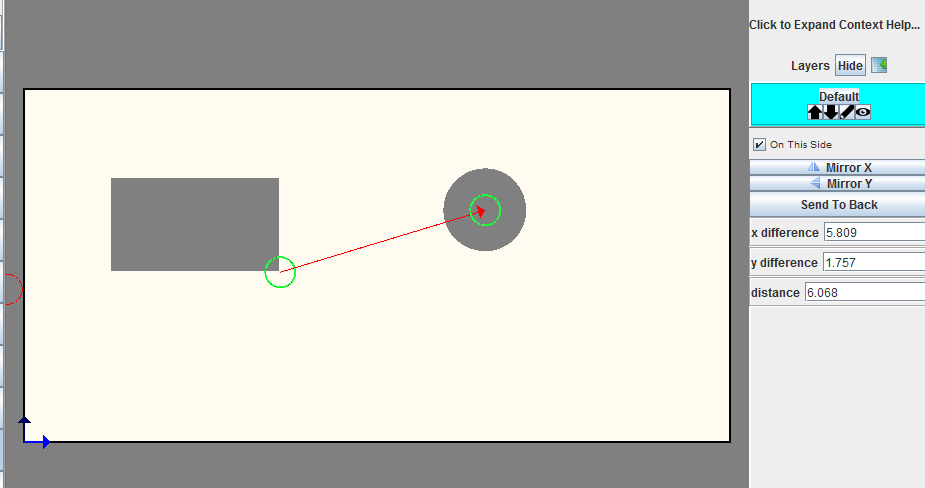

Using the Measure tool to specify both distance and alignment between objects

You can use the Measure tool to specify both distance and alignment between objects. Once you determine the absolute coordinate for one object, the Measure tool lets you place all other objects relative to that, including objects on opposite faces.

- On the Drawing toolbar, click the Measure button.

- On the face, click the start point (the point that is to be the reference point), then click the end point (the point of an object that is to be placed in reference to the starting point).

- Edit the x difference and/or y difference to position the second point in relation to the first. For example, to position an object one inch away from an existing object along both the X and Y axes, enter a y difference of "1" and an x difference of "1".

- Note: If you do not need to measure or specify a distance between two objects, you can align them using the Alignment tools in the Properties panel.

- Note: If you do not need to measure or specify a distance between two objects, you can align them using the Alignment tools in the Properties panel.

See Also

- Using the Measure tool to move an object a specific distance from another object

- Measuring distances

- Dimensions: Displaying measurements for review

- Aligning cutouts on opposite faces

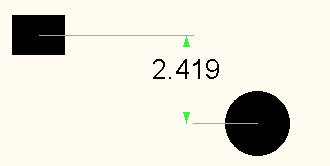

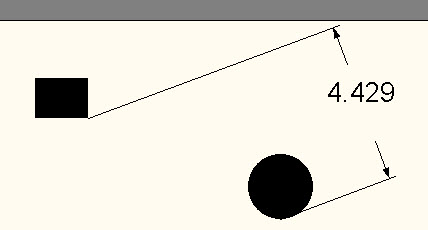

Displaying measurements

You can display the distance between any two points in the Face Editor, using the Dimension button. You can then take a screenshot with the measurements displayed, for peer reviews or other purposes.

To measure and display the distance between two points

- Display the face you want to edit.

- In the Face Editor, click the Dimension button in the Drawing toolbar.

- Click the first endpoint of the distance you wish to measure, then move the cursor.

- As you begin to move the cursor, the distance between the endpoint and the cursor position is displayed.

- If you make an error, click the Undo button in the Face Editor toolbar.

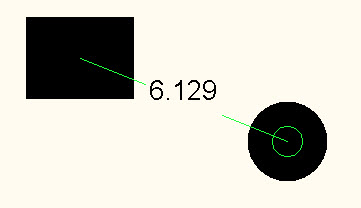

- When the cursor is near an object, it snaps to the important points of the object (its center, or one of the compass points on its outline), a green circle is drawn around the snap-to point, and the lines turn green.

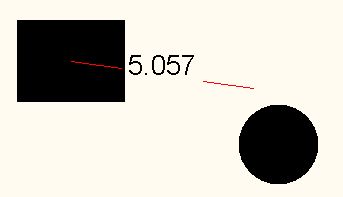

- The lines turn red when the measurement does not have any meaning. There are only three types of measurements that have meaning:

- The distance between the two points;

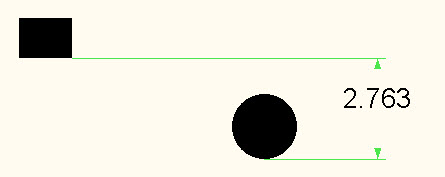

- The distance in the x axis (when the lines are vertical and the arrows are horizontal); and

- The distance in the y axis (when the lines are horizontal and the arrows are vertical).

- Click the second endpoint of the distance you wish to measure.

- When the lines and distance are the way you want them, click the mouse.

- The displayed lines and measurements are saved to the face, and the measurement is reset to 0.000 at the cursor position. You can add more measurements to the screen in this way.

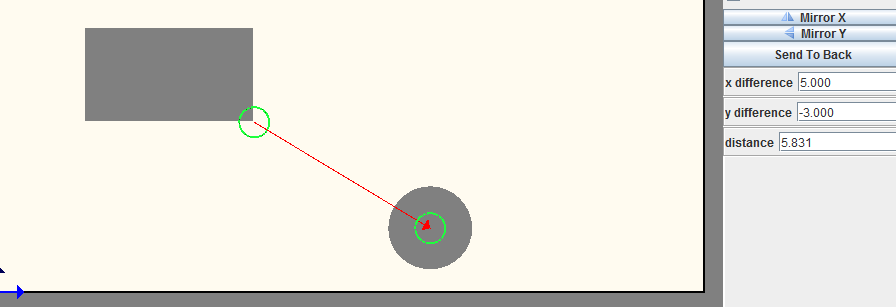

- Tip: You can display the measurement with the lines at an angle to their endpoints. For example, here the distance is shown between the bottom of the rectangle and the bottom of the circle:

- and here the user drags the cursor to a position at an angle:

To delete a displayed measurement

Do either of the following:

- Right-click one of the lines in the measurement and choose Delete from the floating menu.

- Highlight the line and press the Delete key (on your keyboard).

See Also

- Measuring distances

- Using the Measure tool to move an object a specific distance from another object

- Using the Measure tool to specify both distance and alignment between objects

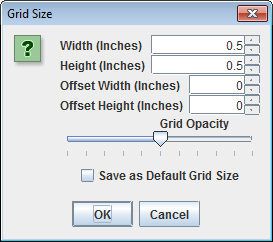

Using the grid

The grid is useful to help accurately place and align objects.

Turn on/off the Grid

- Do one of the following:

- Repeat to toggle the state of the grid.

- Note: Snap to Grid option is automatically enabled when the grid is turned on.

Turning on/off Snap to Grid

Note: Snap to Grid is automatically enabled when the grid is turned on.

- Do one of the following:

- Repeat to toggle the state of Snap to Grid.

Changing grid size and offset

- On the Standard toolbar, click

or choose Grid Size from the Grid menu.

or choose Grid Size from the Grid menu. - In the Grid Size dialog that opens, change any of the following values:

- Width: Horizontal distance between grid lines.

- Height: Vertical distance between grid lines.

- Offset Width: Horizontal offset of grid lines from default grid position.

- Offset Height: Vertical offset of grid lines from default grid position.

- Grid Opacity: Opacity of the grid lines. Move the slider to left for lighter lines or the right for darker lines.

- Save as Default Grid Size: Use the current grid size when editing all faces in the Face Editor Window.

- Note: If you change the Grid Size and do not check Save as Default Grid Size, the grid will revert back to the default size after closing the Face Editor, even if you re-open the same face.

Managing object properties

Top of Properties Panel

Applies to all objects, including silkscreen.

- Click the line that reads "Click to Expand Context Help" to read usage tips for the current object you are editing (circle, ellipse, text, etcetera). Click anywhere in the upper panel again to hide the help.

- For help on the Layers buttons and its toolbar, please see Adding and managing layers.

- The checkbox "On This Side" is selected when the object is on the side that you are editing. Clear the check box to move the object to the other side of the face. Note: The wording of this check box has been changed. Prior to version 4.4.6, it was labeled "OnBottom."

- Tip: You can right-click any object to open a Properties dialog where you can change its absolute origins, Rotation, Height, and/or Width.

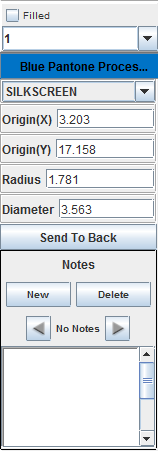

Fill

Applies to silkscreen and construction objects including circles, ellipses, rectangles, and paths.

- Select the check box to fill in the object. The line thickness option is not available when the check box is selected.

Line Thickness

Applies to silkscreen and construction objects including circles, ellipses, rectangles, paths, and lines. Also applies to lines of all object types.

- Select a value from the list below the Filled check box.

Color

Applies to silkscreen objects including circles, ellipses, rectangles, paths, lines, and text.

- Select a color from the Color menu.

- Refer to Stocked Silkscreening Colors for a list of available colours.

Type

Applies to all objects.

- Change the object type by selecting a different type from the list.

- Object types include:

- Cutout

- Silkscreen

- Exclusion

- Construction

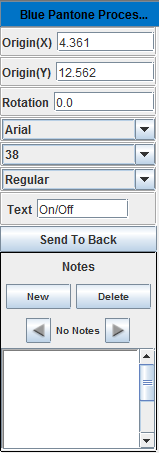

Origin

Applies to all objects.

- Change the location of the X and Y origins with respect to the absolute coordinate system.

- Enter a number and press the Tab key to accept.

- The origin of an object is indicated by a red square.

- The origin for each object is determined as follows:

- Circles -- centre

- Ellipses -- centre

- Rectangles -- corner closes to the absolute origin

- Text -- bottom left corner

- Paths -- start point

- Lines -- start point

- Images -- bottom left corner

Circles

- Radius, Diameter -- Changing one of these properties will automatically update the other. Diameter is twice the radius.

Ellipses

- RadiusX -- Radius along X-axis (defines horizontal length).

- RadiusY -- Radius along Y-axis (defines vertical length).

Rectangles

- Width, Height -- Width and Height of the object.

- Rotation -- Angle with respect to origin in degrees. Positive value rotates object clockwise and negative value rotates object counter-clockwise

Lines

- Length -- Distance from origin to end point.

Images

- Width, Height -- Width and height of the object.

- Rotation -- Angle with respect to origin in degrees. Positive value rotates object clockwise and negative value rotates object counter-clockwise

Text

- Rotation -- Angle with respect to origin in degrees. Positive value rotates object clockwise and negative value rotates object counter-clockwise

- Font -- Change the font to Arial, Courier, Garamond, Avant Garde, Times New Roman, Palatino, or Bookman. Unicode characters (language scripts, punctuation marks, diacritics, mathematical and technical symbols, etc.) are supported.

- Font Size -- Change the font size within the available range of 9-99 points. Note: Available font sizes are based on quality for the given materials. For example, Times Roman, the currently supported serif font, requires a minimum font size of 11 points. In addition, a minimum font size of 11 points is required for printing on top of any powdercoat that has "Sandtex" in its name. To use a smaller font, you must specify a non-serif font (such as Ariel) and a smooth powdercoat.

- Font Style -- Change the font style to Regular, Bold, Bold Italic, or Italic.

- Text -- Change the text to appear on the face. Press the Tab key to accept.

Path

- Rotation -- Angle with respect to origin in degrees. Positive value rotates object clockwise and negative value rotates object counter-clockwise

Adding notes to objects

You can add Notes to objects to communicate your design intentions to the Protocase tech team. For example:

- "Round the corners of this rectangle to a radius of .05 inches."

- "Put a hinged door over this cutout."

- "Put rubber feet on this face.”

Each note is related to one specific object. Each object can have multiple notes.

Important! If your notes result in significant design changes (such as a request for a non-stocked item), the quote that Protocase Designer generates automatically might not be accurate. The quote the tech gives you after you submit the file will be correct.

To add a note to an object

- In the Face Editor, select the object that needs a note. The Properties panel then displays the Notes tools:

- Type the note in the blank text window. If the object already has a note, it will be displayed in the text window; to add another note to the object, click the New button, which clears the text window so you can enter another note.

- Every note you enter is saved with the object. If the object has multiple notes, use the forward and back arrows to view them. You can edit each note at any time.

- Every note you enter is saved with the object. If the object has multiple notes, use the forward and back arrows to view them. You can edit each note at any time.

To delete a note

- Display the note, then click the Delete button.

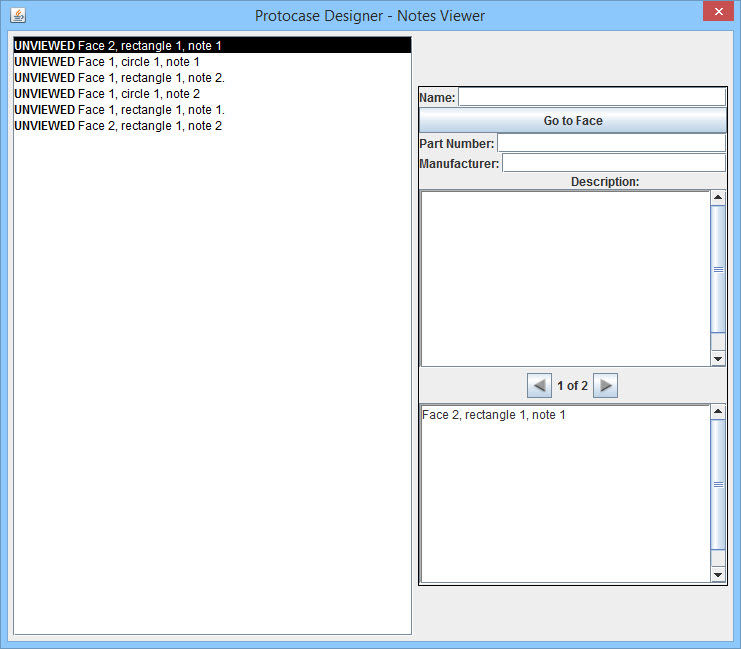

To review all notes for a design

- In the 3D Editor, select View > View Notes. The Notes Viewer window opens, where you can see all notes for all faces at a glance.

- To go to the object and its notes in the Face Editor, highlight any note for the object, then click the Go to Face button. The Face Editor will open, with the object selected.

Adding cutouts

You can add built-in and custom cutouts to your enclosure.

See Also:

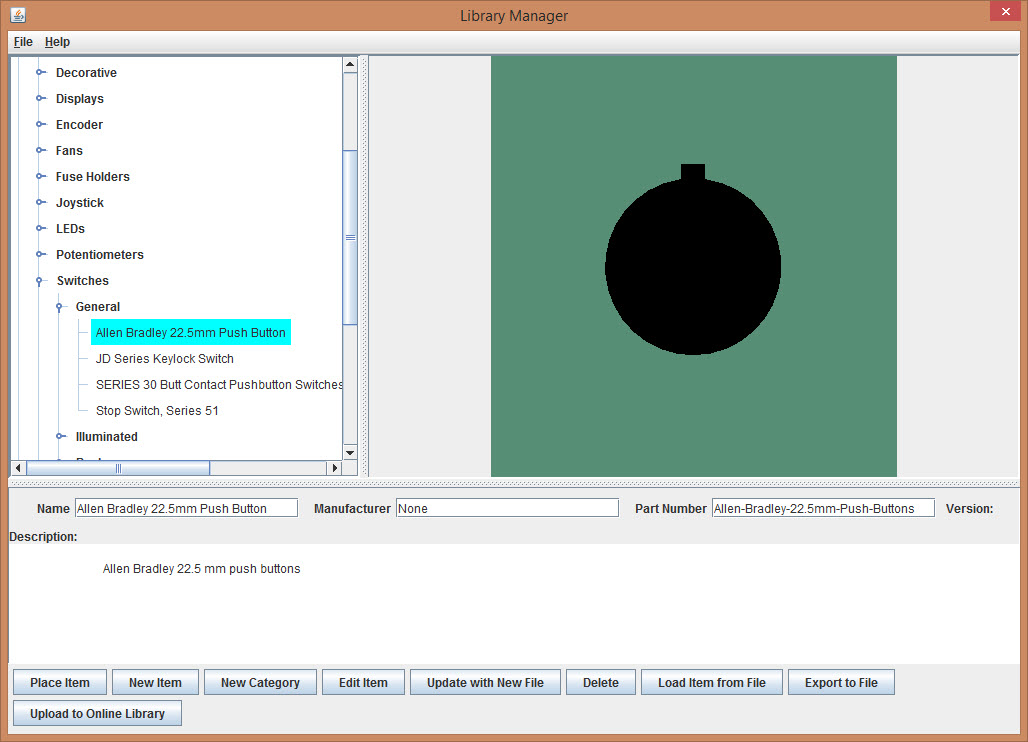

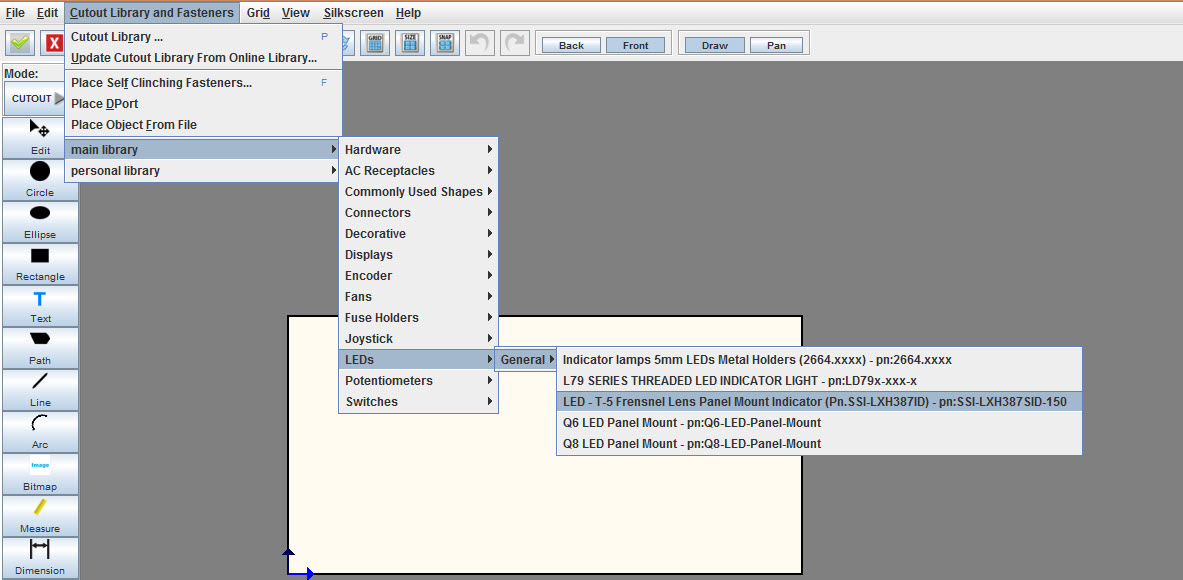

To add a cutout by browsing the Cutout Library

Use this method to get a summary description and image of each item in the library.

- In the Face Editor, choose Cutout Library and Fasteners > Cutout Library.

- Browse through the listings, clicking any one you are interested in to display it and its description.

- Click the Place Item button to load the displayed cutout.

- Click on the face in each location where you want to place the cutout.

- When you are done, press <Esc> or click any drawing tool to exit the placement process.

To add a cutout by selecting it from the menu

Use this method when you know exactly which cutout you want to load.

- In the Face Editor, drill down through the Cutout Library and Fasteners > main library or personal library listings, and click on the name of the cutout that you want to load.

- The cursor changes to an image of the cutout; click each location on the face where you want to place the cutout.

- When you are done, press <Esc> or click any drawing tool to exit the placement process.

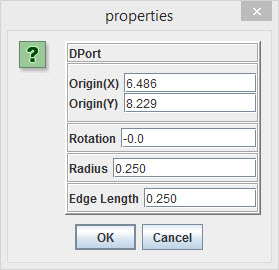

Adding "D" port cutouts

You can add a "D"-shaped cutout (a circle with one side flattened) to your enclosure design.

- In the Face Editor, choose Place DPort from the Cutout Library and Fasteners menu and place it on the face.

- The D-cutout is added in a default size.

- To edit the cutout, right-click the cutout and choose Properties. (The Radius and Edge Length are not currently available in the right-hand Context panel.)

- To change the radius of the circle, edit Radius.

- To change the length of the straight cut, edit Edge Length.

- To change the position, use the Origin(X) and Origin(Y) fields.

- To rotate the cutout, in the Rotate field enter the degrees, preceded by a negative sign if you want to rotate it counter-clockwise.

- Note Incorrect error messages might be displayed for the D cutout, such as "Some objects may be outside the face boundary or overlapping keepout zones after this operation." Do a visual check on the design in the Face Editor and/or 3D View, and if it seems correct to you, ignore the message.

See Also: Creating Double-D cutouts

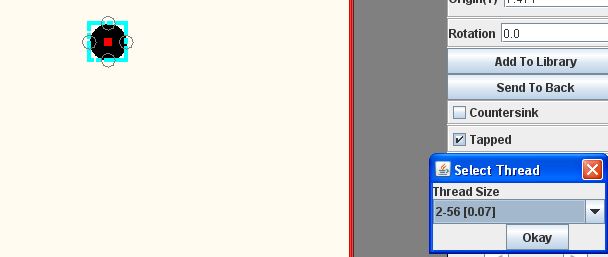

Adding countersinks and tapped holes

Important! Tapping holes in thin sheet metal is not recommended, since it is too thin for threads. Please consider using a self-clinching nut instead.

Notes on Screws:

- Screws are included in each template (along with its hole cutout), and do not have to be added manually. If you do place a screw manually, the hole is also placed automatically, but the 3D image does not show the kind of thread or screw (e.g., Phillips or Flathead).

- A Flathead screw will be countersunk by default. Even if you choose an enclosure with a different default screw and change it to Flathead, it will use a countersunk screw.

- You cannot replace a screw with another screw; you can only replace it with a self-clinching fastener.

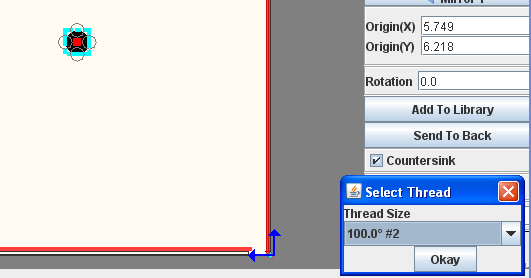

To add a countersink to a face

- In the Face Editor, choose the face you want, and draw a circle for the countersink hole.

- Select the new Countersink check box in the Properties panel.

- Click OK to select the default, or click the down-arrow to select a different size and then click OK.

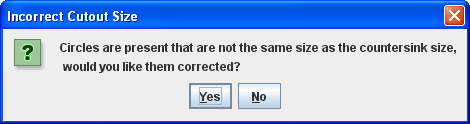

- Note: Thread Size includes the angle of the countersink on the head, and the standard thread size. For example, a thread size of "100.0° #2" indicates a countersink angle of 100 degrees, with the standard #2 thread size.)

- If you chose a countersink size that is not the same size as the hole, a warning message is displayed and you are given the option to correct it. Click Yes to have the hole size changed to match the selected countersink size. Click No if you want a different tolerance than is specified for the screw.

To add multiple countersinks to a face

- To add multiple countersinks to a face at one time, draw a circle for each hole, click the Edit button, select all circles, and then click the Countersink check box.

To add a tapped hole to a face

- In the Face Editor, choose the face you want, and draw a circle for the tapped hole.

- Select the new Tapped check box.

- Click OK to select the default, or click the down-arrow to select a different size and then click OK.

- Note: Thread Size includes the hole diameter along with the standard screw types. For example, a thread size of "2-56 [0.07]" indicates the standard 2-56 screw type with a diameter of 0.07" for the threaded hole. The minor diameter is used along with some tolerance so that it does not bind.

- If you chose a thread size that is not the same size as the circle, a warning message is displayed and you are given the option to correct it. Click Yes to have the circle changed to match the selected thread size. Click No if you want a different tolerance than is specified for the screw. (Important! In versions 4.4.9-Jul07 and higher, you are no longer given the option to change the hole size. It must be the same size as the circle.)

- The tapped hole is drawn on the face.

- The tapped hole is drawn on the face.

To add multiple tapped holes to a face

- To add multiple tapped holes to a face at one time, draw a circle for each hole, click the Edit button, select all circles, and then click the Tapped Hole check box.

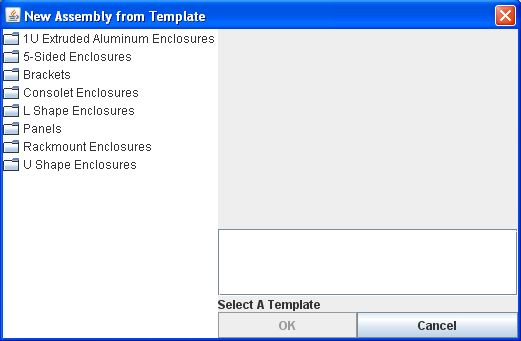

Creating and adding brackets

You can create customized brackets with cutouts and other elements and save them to the Cutout and Fasteners Library. You can then add them to enclosures at any point.

To create and save a customized bracket

- Click New.

- Choose the bracket that you want to customize, and then edit its parameters (Width, Depth, Height, etc.) as necessary.

- Add elements (cutouts for mounting, standoffs, etc.) as necessary to each face. When done, click the Accept Changes button.

- The 3D View window opens.

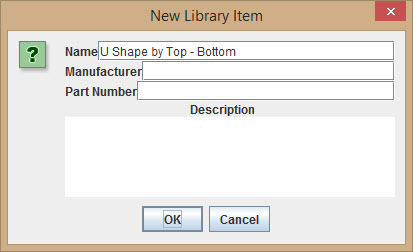

- Choose Create Subassembly from the Cutout Library Manager menu.

- You are prompted to select the face that is the mating face (that mounts onto the enclosure); click OK and then do so.

- You can enter or edit the following information for the bracket:

- Name: Note that the default name provides an indication of the mating face (such as "L Bracket by Front - Bottom" or "L Bracket by Base - Top"), but we recommend that you change this to ensure it remains unique.

- Manufacturer

- Part Number

- Description

- Click OK.

- You receive a message that the bracket has been added to your library. It is now listed in the Cutout Library and Fasteners menu.

- Note On Bracket Origin and Placement: The default origin for placement is the default origin of the bracket template. In the 3D View, the origin is displayed with a red dot and arrows. In the Face Editor, the origin is displayed with blue arrows, and the x and y values in the Properties panel refer to this origin point. When placing the bracket on an enclosure, the origin will be placed precisely where you click the enclosure face.

- You receive a message that the bracket has been added to your library. It is now listed in the Cutout Library and Fasteners menu.

To place a bracket on the enclosure

- Load the enclosure and select the face to which you will add the bracket.

- Note: If you have just saved a bracket to the library, it remains displayed, and when you click New to load an enclosure, you are prompted to save the current project. If you plan on making further changes to the bracket later, do save the bracket as a project, since currently you cannot use the editing tool in the Cutout Library to edit it. (This will be fixed in a future release.)

- In the Face Editor, make sure the correct Inside or Outside is selected for the bracket placement.

- From the Cutout Library and Fasteners menu, choose Cutout Library. The Library Manager window opens; select the bracket that you want to add to the enclosure. (The customized brackets that you saved to the library are listed in the personal library section.)

- Click the Place Item button.

- The footprint (outline) of the mating face of the bracket is displayed as the cursor icon.

- Move the cursor (the footprint moves with it) to the desired location and click to drop it there; as noted above, the origin point of the bracket will be placed where you click. You can add multiple brackets in this way.

Adding hardware

You can easily add hardware on your enclosure to accommodate various components, such as self-clinching fasteners to mount a PCB or handles. Protocase uses common PEM® brand self-clinching fasteners.

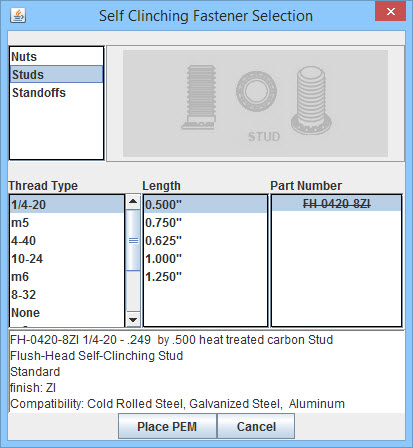

Adding self-clinching fasteners

- In the Face Editor, choose Cutout Library and Fasteners > Place Self Clinching Fasteners.

- Select the type (Nuts, Standoffs, or Studs) and then select the Thread Type.

- If you are adding standoffs or studs, the available thread Lengths are displayed. (Nuts do not have thread lengths, so if you are adding a nut, skip the next step.)

- Select the thread Length.

- The available Part Numbers are displayed.

- Select a Part Number.

- Note: Parts displayed with strikeout through the name are incompatible with the enclosure's current material type and/or thickness, and cannot be selected. If you continue with the incompatible design, you will receive a design check error when you estimate, order, or use the design check feature.

- Because fasteners have a minimum metal thickness, larger fasteners are not listed if the current enclosure material is too thin for them, or if the material is stainless steel and the fastener is zinc-coated. (Zinc-coated fastener names end with "ZI".) Some materials, especially stainless steel, require special fasteners. These cost a little more than standard ones.

- Note: Parts displayed with strikeout through the name are incompatible with the enclosure's current material type and/or thickness, and cannot be selected. If you continue with the incompatible design, you will receive a design check error when you estimate, order, or use the design check feature.

- Click the Place PEM button, and then click on the face wherever you want to add the fastener(s). Note that if you try to place fasteners that are incompatible with the enclosure material, you receive a warning, as you did when you selected the incompatible Part Number.

- When you are done adding fasteners, click the Edit button

or press the Esc key.

or press the Esc key.

Adding mounting hardware

- On the Standard toolbar, click Edit Face

and click a face to edit.

and click a face to edit. - On the Standard toolbar, click Toggle Grid

to show the grid and automatically turn on snap to grid.

to show the grid and automatically turn on snap to grid. - On the Cutout Library and Fasteners menu, point to Hardware, then click a hardware item.

- Continue adding mounting hardware and select the Edit tool

when you are done.

when you are done.

Manipulating objects

Selecting object(s)

- On the Drawing toolbar, select the Edit tool.

- Do one of the following:

- To select a filled object, click anywhere on the object.

- To select an unfilled object, click the border of the object.

- To select multiple objects:

- click the first object, press and hold down the <Shift> key, then click other objects; or

- click and drag a selection box over several objects

Editing object(s)

To edit a single object

- Click the Edit button in the left-hand toolbar.

or

- Click the object to select it, then edit any of the fields in the Properties panel.

or

- Right-click the object and choose Properties from the floating menu.

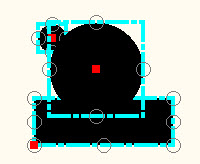

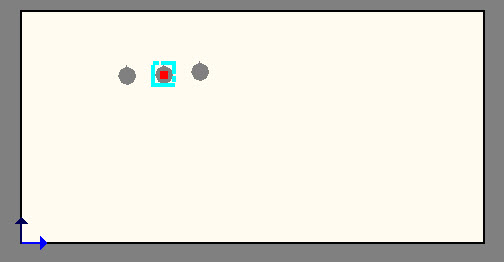

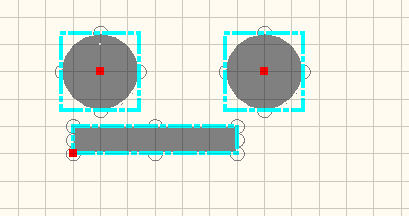

When selected, a light blue box is drawn around the object, its origin is displayed in red, and circles are drawn around each node.

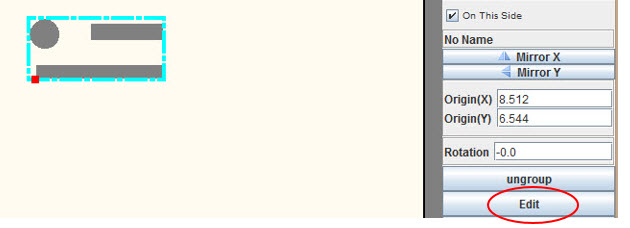

To edit a group of objects

- Select the group.

- Click the Edit button in the Properties panel.

- When done editing the objects in the group, click Accept and Close

in the top toolbar.

in the top toolbar.

- The Cutout Editor is closed and the group is displayed in the Face Editor.

- The Cutout Editor is closed and the group is displayed in the Face Editor.

or

- Ungroup the items, edit them individually, then regroup the items. See Grouping and ungrouping objects.

Moving object(s)

To move a single object:

- Select the object.

- Click anywhere on the object and drag to the desired location.

To move several objects:

- Select all the objects.

- Press and hold the Shift key, then click any of the objects and drag to the desired location.

To move cutouts from one face to another:

- On each face that you want to switch, group the items, add the group as a single cutout to your cutout library, then delete the items.

- Add each grouped cutout from the Cutout Library to the desired face, then use the Measure tool to adjust the placement. Once the placement is correct, you can ungroup the items so they are easier to work with.

- For detailed instructions, see:

Grouping and ungrouping objects

To group objects

- Click the Edit button in the left-hand toolbar.

- Click and drag the mouse to draw a box around the objects you want to group, or hold down the <Shift> key and select each object.

- Click the Group button in the Properties panel.

To ungroup objects

- Click the Edit button in the left-hand toolbar.

- Click the group.

- Click the ungroup button in the Properties panel.

See Also

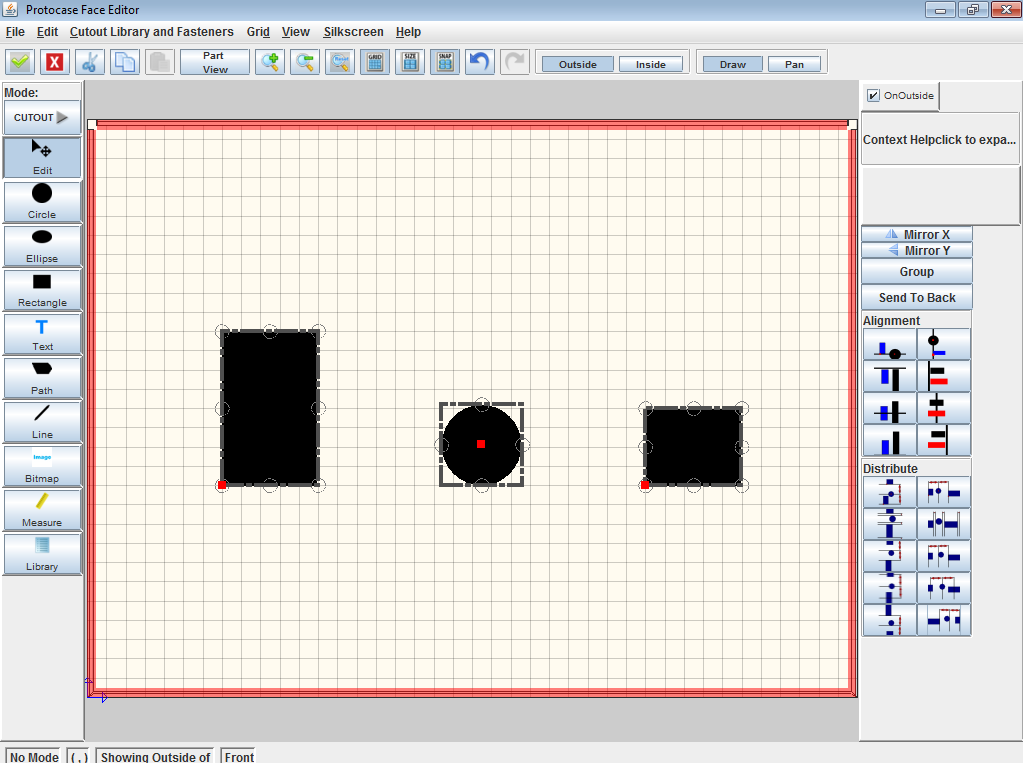

Aligning and distributing objects

You can arrange objects on a face using the Alignment and Distribute commands.

- Select 2 or more objects. The Alignment and Distribute commands appear on the Properties panel.

- On the Properties panel, click an alignment or distribute command.

Alignment

![]() Align Origins of Objects Vertically

Align Origins of Objects Vertically

![]() Align Tops of Objects

Align Tops of Objects

![]() Align Centers of Objects Vertically

Align Centers of Objects Vertically

![]() Align Bottoms of Objects

Align Bottoms of Objects

![]() Align Origins of Objects Horizontally

Align Origins of Objects Horizontally

![]() Align Left Sides of Objects

Align Left Sides of Objects

![]() Align Centers of Objects Horizontally

Align Centers of Objects Horizontally

![]() Align Right Sides of Objects

Align Right Sides of Objects

Notes:

- Objects align to first object selected

- When using the selection marquee, objects align to the last object created.

Distribute

![]() Distribute Origins Vertically

Distribute Origins Vertically

![]() Distribute Space Vertically

Distribute Space Vertically

![]() Distribute Distance Between Tops

Distribute Distance Between Tops

![]() Distribute Centers Vertically

Distribute Centers Vertically

![]() Distribute Bottoms of Objects

Distribute Bottoms of Objects

![]() Distribute Origins Horizontally

Distribute Origins Horizontally

![]() Distribute Space Horizontally

Distribute Space Horizontally

![]() Distribute Left Sides of Objects

Distribute Left Sides of Objects

![]() Distribute Centers Horizontally

Distribute Centers Horizontally

![]() Distribute Right Side of Objects

Distribute Right Side of Objects

Cutting, copying, and pasting objects

Use the Cut, Copy, and Paste commands to easily create multiple copies of objects.

- Select one or more objects.

- On the Edit menu, select Cut, Copy, or Paste. A copy of the object(s) will appear next to the cursor.

- Click to place the object(s) on the face.

- Continue placing object(s) on the face and select the Edit tool

when you are done.

when you are done.

Undoing and Redoing actions

Click the Undo ![]() or Redo

or Redo ![]() button in the Face Editor toolbar, or choose Undo or Redo from the Edit menu.

button in the Face Editor toolbar, or choose Undo or Redo from the Edit menu.

Adding and managing layers

When working with complex designs, layering lets you group similar elements and hide all other elements in the editor. It can also affect the end product, depending on what is being layered. The default layer is always present and is always used first.

Layer Toolbar

Each layer has its own toolbar, with the following buttons:

Move the layer up in the list.

Move the layer up in the list.  Move the layer down in the list. Note: The two Move buttons position the layers in the order that they will be produced, and in the order that they are drawn on the screen. The one exception to this is that cutouts are always displayed on top.

Move the layer down in the list. Note: The two Move buttons position the layers in the order that they will be produced, and in the order that they are drawn on the screen. The one exception to this is that cutouts are always displayed on top. Edit the layer.

Edit the layer. Show/hide the layer. (This is a toggle button.)

Show/hide the layer. (This is a toggle button.)  Delete the layer.

Delete the layer.

To add a new layer

- In the Face Editor, click the (unlabeled) New Layer button at the top of the Properties panel.

- File:Controls-Layers-FaceEditor.jpg

- The Input dialog opens.

- Enter a name for the layer (examples you might use: Output, Input, Buttons, Silkscreen, Power, Lights).

- The layer is added to the Properties panel with its toolbar, and is automatically selected as the current layer.

To copy and paste between layers

- Cut or copy the object(s) from one layer.

- Select the layer where you want the object(s) to be placed.

- Paste the object(s).

Important! When working with layers, be sure to check which layer you are working on before making any edits. The current layer is highlighted in the list.

Printing one or more faces on paper for review

To print one face, or all faces, of the enclosure

- To print a single face, display the face in the Face Editor and choose Print To Scale from the File menu. To print all faces of the enclosure, choose the same command in the 3D View window.

- In the dialog that opens, select the printer.

- When verifying a design, set the Absolute Scale to 100%, then tape together the multiple sheets that are printed. To make a small-scale model, set it to 50% or whatever scale you want.

- Click Print.

To calibrate the printer

Many printing devices do not print the correct size even when you specify 100%. Before you print a face, be sure to calibrate your printer.

- In the Print to Scale dialog, select the printer, then click the Calibrate Printer button.

- A test page opens.

- Click Print to print the test page. Then use a ruler or caliper to measure the width and height of the printed rectangle.

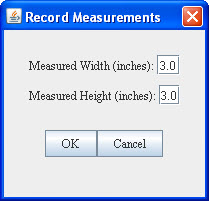

- The Record Measurements dialog opens.

- If the printed rectangle is not 3" x 3", then enter the Measured Width (in inches) and the Measured Height (in inches) and click OK.

Exporting and importing face templates

Exporting a face template

You can export a face to a .PGN image file for editing in a third-party graphics editor, and you can import the edited image back into the Face Editor. This feature is useful when reviewing designs, using in presentations, or editing a face in an external graphics program. For example, you can export an image file with all the cutouts on it, add graphics to that image in your favorit graphics editor, and import it back in.

- Make sure the face you want to export is displayed in the Face Editor.

- Select Silkscreen > Export silkscreen template. The Save dialog opens.

- Enter a name for the image file and click Save. A properly scaled .PNG image of the face is created, complete with all cutouts.

- Note The exported image displays the cutout areas in the color pink (hexadecimal value FF9999). This is the one color you cannot use for your graphics ink, because Protocase Designer will always recognize this color as a cutout and never as a graphic.

Adding graphics to a face using a graphics editor

You can add graphic elements to a face using a separate graphics editor (such as Adobe Illustrator or Photoshop) that can edit a .PNG file. For each face requiring silkscreen or digital print, you export the face with its cutouts, add the graphical elements to the image using your graphics editor, and import the revised image back into Protocase Designer.

- First, follow the steps in Exporting a face template.

- Open the file with your graphics editor and add the images/text to be silkscreened or printed, aligning them with their corresponding cutouts.

- When done editing, save the file again in .PNG format.

- In the Face Editor, select Silkscreen > Import silkscreen template and choose the .PNG file you just saved. The image with both cutouts and graphics is displayed in the Face Editor.

- If you need to make additional changes, edit the .PNG file again in your graphics editor, and re-import it to the Face Editor. (You do not need to remove it from Protocase Designer first; it will be automatically replaced by the most recently imported file, as long as it has the same name.)

Note: When importing any image for silkscreening or digital printing, be sure to read the tips in Tell me about silkscreening or digital printing.

See Also: Adding silkscreening or direct digital printing

Face Editor preferences

You can change several parameters for controlling the Face Editor functionality.

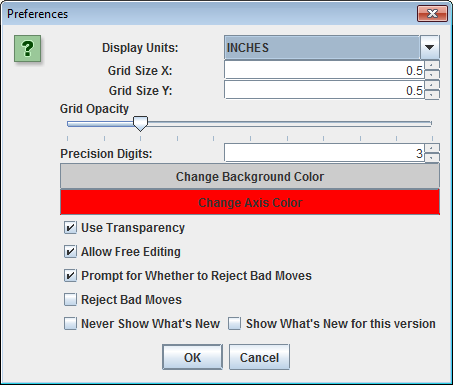

- On the Edit Menu, click Preferences.

- In the Preferences dialog box, change any of the following values:

- Display Units: Used for drawing/editing objects and measuring distances. Choose INCHES, CM, or MM.

- Grid Size X, Grid Size Y: The horizontal and vertical space between grid lines. Type a number or click the up/down arrows to change the value in 0.1 increments.

- Precision Digits: The number of units displayed when drawing/editing objects and measuring distances. Type a number or click the up/down arrows to change the value in 0.1 increments.

- Grid Opacity: Opacity of the grid lines. Move the slider to left for lighter lines or the right for darker lines.

- Allow Free Editing: Enable or disable the ability to move or change the size of objects directly on the face. Clear the check box to prevent accidentally moving or changing the size of objects.

- Prompt for Whether to Reject Bad Moves: Displays a warning if you move an object outside a face boundary or overlapping an exclusion zone.

- Reject Bad Moves: Prevents you from moving an object outside a face boundary or overlapping an exclusion zone. The object is automatically moved back to its original position.

- Never Show What's New: Disables a dialog at startup showing the new features of Protocase Designer.

- Show What's New for this version: Displays a dialog at startup showing the new features for the current version of Protocase Designer.