Selecting height of self-clinching fasteners based on material thickness

From Protocase Designer Documentation

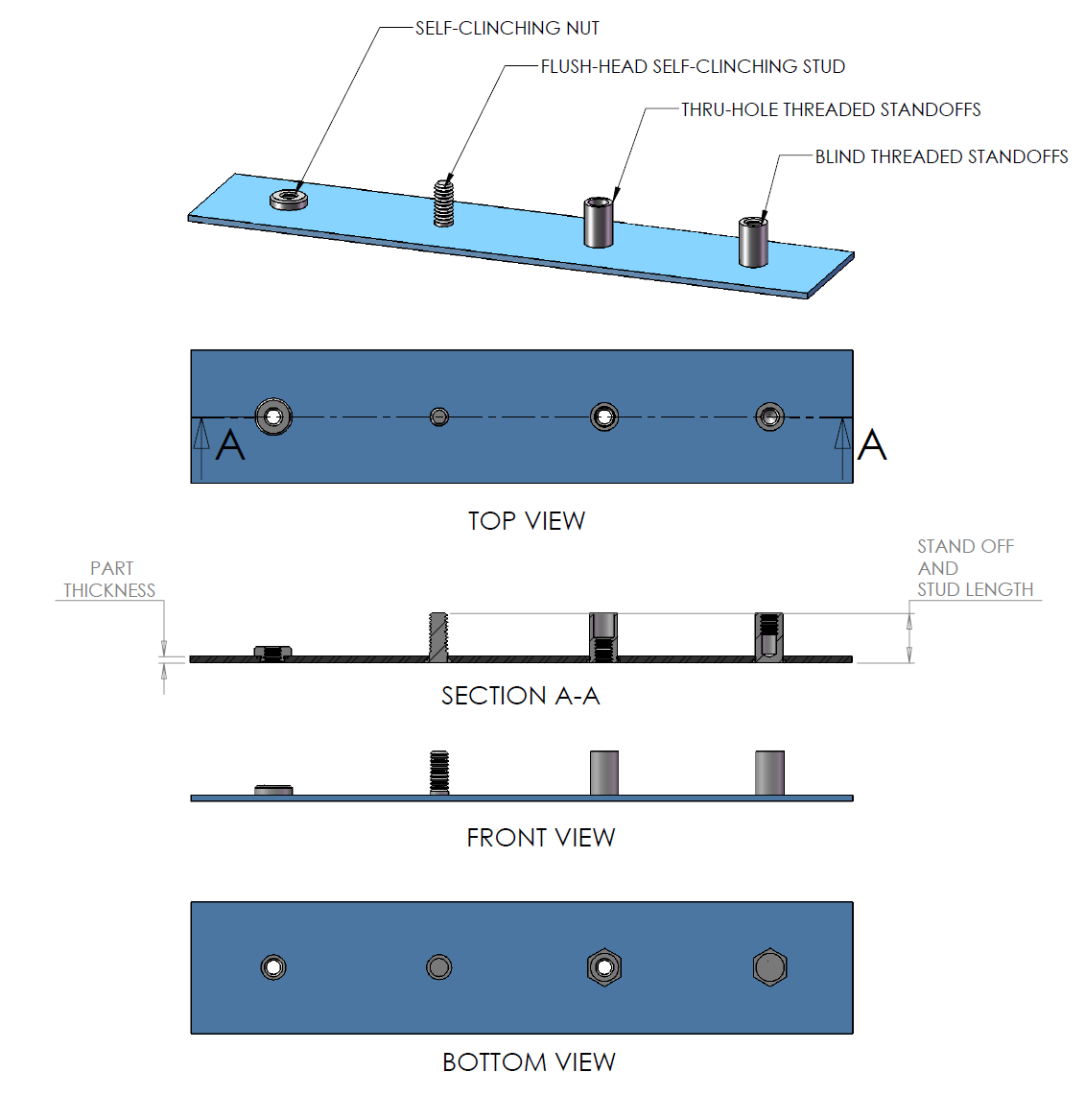

Self-clinching fasteners are threaded nuts, studs, or standoffs that are mechanically pressed into sheet metal to provide solid fastening points. Nuts can be used to accept bolts, standoffs can be inserted for mounting circuit boards, and studs can be used for mounting connectors.

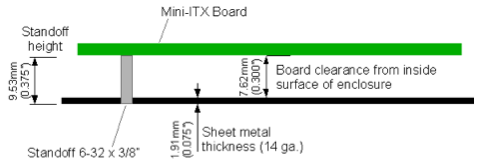

- Usually, self-clinching standoffs or studs are inserted from the outside of the face through to the inside. In this case, you must consider the material thickness when you select the height of the fasteners, to ensure there is sufficient clearance between the fasteners and any component (such as a circuit board) on the inside of the enclosure. To calculate the actual clearance between a component and the enclosure, subtract the metal thickness from the height of the fastener. For example, a 0.375" (9.53mm) standoff, mounted in a 14-gauge (0.075") enclosure wall will provide 0.300" (7.62mm) clearance to a component, and less if the metal is thicker.

- Self-clinching fasteners cannot be placed too close to an edge. However, there is no single rule that works for all fasteners; every part has its own restrictions. A larger fastener might not be able to be closer than 0.4" (10 mm) from an edge, whereas a smaller fastener may have a limit around 0.23" (6 mm). If you have any doubt about a part being too close to an edge, contact info@protocase.com to find out if it can be placed.

Protocase offers a wide variety of self-clinching fasteners for use in your enclosure designs.

See Also: