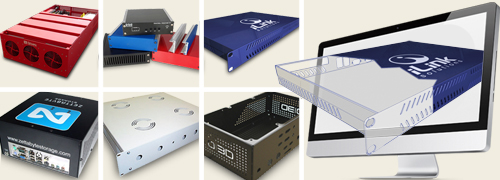

The fastest and easiest way to design, price and build custom electronics enclosures.

The fastest and easiest way to design, price and build custom electronics enclosures.

Conventional Fasteners

Protocase stocks a wide variety of conventional fasteners, and if we don't stock it, we have access to just about any common fastener on a quick-delivery. The most commonly used items are machine screws and hex nuts, which are listed in the table below.

Self-tapping screws vs. machine screw / self-clinching nut combination

In certain situations, a designer has the option of using either

- a combination of self clinching nut and machine screw, or

- a self-tapping screw, as shown in the diagram.

We highly recommend option (A), for the following reasons:

- Self tapping screws are subject to stripping

- They interfere with finishes, breaking through powdercoating, and creating potential corrosion problems.

- Inconsistent removal torque --- they can lock in place, and be extremely difficult to remove.

The self tapping screw option is slightly less expensive, but the disadvantages far outweigh the slight savings for most applications. Thus the only place we would ever recommend Option (B) is when searching for cost-engineering solutions on volume orders.

Please note: To view our stocked inventory of conventional fasteners, plese visit protocase.com on a desktop or laptop computer.

Recently added inventory is colored blue.

Most Commonly Used Fasteners

| Part Name | Description | Thread Size | Thread Length | Materials NOT Compatible |

| 90480A003 | Hex Nut 2-56 Steel Zinc | 2-56 | Stainless Cold-rolled Aluminum | |

| MS_2-56_1/4in_PPH_18-8SS | Machine Screw 2-56 x 1/4in Phillips Pan Head 18-8 Stainless | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 2-56X1/4PAN PH SS B0 | Machine Screw 2-56 x 1/4in Phillips Pan Head 18-8 Stainless Black Oxide | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 2-56X1/4PAN PH ST ZC | Machine Screw 2-56 x 1/4in Phillips Pan Head Steel Zinc | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 2-56X1/4FT1 PH SS B0 | Machine Screw 2-56 x 1/4in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| FCMP0204 | Machine Screw 2-56 x 1/4in Phillips Flat Head 100° Steel Zinc | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 2-56x1/4FT1 PH SS PS | Machine Screw 2-56 x 1/4in Phillips Flat Head 100° 18-8 Stainless | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 2-56X1/4FLT PH SS B0 | Machine Screw 2-56 x 1/4in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| FMSP0204 | Machine Screw 2-56 x 1/4in Phillips Flat Head 82° 18-8 Stainless | 2-56 | .250 | Stainless Cold-rolled Aluminum |

| 91771A110 | Machine Screw 4-40 x 1/2in Phillips Flat Head 82° 18-8 Stainless | 4-40 | Stainless Cold-rolled Aluminum | |

| 90631A005 | Low-Strength Steel Nylon-Insert Locknut Zinc-Plated, 4-40 Thread Size | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X3/8PAN PH SS B0 | Machine Screw 4-40 x 3/8in Phillips Pan Head 18-8 Stainless Black Oxide | 4-40 | Stainless Cold-rolled Aluminum | |

| 91240A005 | Mil Spec. Hex Nut 4-40 18-8 Stainless (MS-35649-244) 1/4in Wide, 3/32in High | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X3/16PAN PH SS B0 | Machine Screw 4-40 x 3/16in Phillips Pan Head 18-8 Stainless Black Oxide | 4-40 | Stainless Cold-rolled Aluminum | |

| 0MAS04400250FLP01BX | Machine Screw 4-40 x 1/4in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X1/4FLT PH ST ZC | Machine Screw 4-40 x 1/4in Phillips Flat Head 82° Steel Zinc | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X1/4FT1 PH SS B0 | Machine Screw 4-40 x 1/4in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40 x 1/4in FlatHead Stainless 100° | Machine Screw 4-40 x 1/4in Phillips Flat Head 100° 18-8 Stainless | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40M/S ST ZC | Hex Nut 4-40 Steel Zinc | 4-40 | Stainless Cold-rolled Aluminum | |

| 93365A120 | Tapered Heat-Set Inserts for Plastic 4-40 Thread Size, 0.135in Installed Length, Brass | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40M/S SS PS | Hex Nut 4-40 18-8 Stainless | 4-40 | Stainless Cold-rolled Aluminum | |

| 0MAS04400375PNP40ZR | Machine Screw 4-40 x 3/8in Phillips Pan Head Steel Zinc | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X5/8FLT PF ST B0 | Machine Screw 4-40 x 5/8in Phillips Flat Head 82° Steel Black Oxide | 4-40 | Stainless Cold-rolled Aluminum | |

| 4-40X5/16FT1 PH SS PS | Machine Screw 4-40 x 5/16in Phillips Flat Head 100° 18-8 Stainless | 4-40 | Stainless Cold-rolled Aluminum | |

| 93365A230 | Tapered Heat-Set Inserts for Plastic 4-40 Thread Size, 0.285in Installed Length, Brass | 4-40 | Stainless Cold-rolled Aluminum | |

| 95345A021 | Machine Screw with Lock Washer (internal tooth) 4-40 x 3/16in Phillips Pan Head 18-8 Stainless | 4-40 | .187 | Stainless Cold-rolled Aluminum |

| 93085A105 | Mil Spec. Machine Screw 4-40 x 3/16in Phillips Flat Head 100° 18-8 Stainless (MS-24693-C1) | 4-40 | .187 | Cold-rolled Aluminum |

| 0MAS04400187FCP0100 | Machine Screw 4-40 x 3/16in Phillips Flat Head 100° 18-8 Stainless (0MAS04400187FCP01000) | 4-40 | .187 | Stainless |

| 98286A416 | Machine Screw 4-40 x 3/16in Phillips Flat Head 100° Black Nylon | 4-40 | .187 | Stainless Cold-rolled Aluminum |

| 96640A052 | Machine Screw 4-40 x 3/16in Phillips Flat Head Undercut 82° 18-8 Stainless Black Oxide | 4-40 | .187 | |

| 4-40 x 1/4 MACHINE SCREW FLAT 100 PHIL STEEL BLACK ZINC ROHS | Machine Screw 4-40 x 1/4in Phillips Flat Head 100° Steel Black Zinc | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| MSPPK0404 | Machine Screw 4-40 x 1/4in Phillips Pan Head 18-8 Stainless Black Oxide | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| 4-40X1/4PAN PH ST ZC | Machine Screw 4-40 x 1/4in Phillips Pan Head Steel Zinc | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| 4-40X1/4PAN PH SS PS | Machine Screw 4-40 x 1/4in Phillips Pan Head 18-8 Stainless | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| 4-40X1/4FT1 PH ST ZC | Machine Screw 4-40 x 1/4in Phillips Flat Head 100° Steel Zinc | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| 18-8 SS Flat Head (82deg) Phillips Machine Screw 4-40 Thread, 1/4in Length | Machine Screw 4-40 x 1/4in Phillips Flat Head 82° 18-8 Stainless | 4-40 | .250 | Stainless Cold-rolled Aluminum |

| 91771A107 | Machine Screw 4-40 x 5/16in Phillips Flat Head 82° 18-8 Stainless | 4-40 | .312 | Stainless Cold-rolled Aluminum |

| 93085A108 | Mil Spec. Machine Screw 4-40 x 3/8in Phillips Flat Head 100° 18-8 Stainless (MS-24693-C4) | 4-40 | .375 | Stainless Cold-rolled Aluminum |

| SPX1150A | 4-40 x 3/8in Phillips Pan head, Nylon | 4-40 | .375 | Stainless Cold-rolled Aluminum |

| 18-8 SS Flat Head (82deg) Phillips Machine Screw 4-40 Thread, 3/8in Length | Machine Screw 4-40 x 3/8in Phillips Flat Head 82° 18-8 Stainless | 4-40 | .375 | Stainless Cold-rolled Aluminum |

| 4-40 x 3/8 FlatHead 100° 18-8SS BlackOX | Machine Screw 4-40 x 3/8in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 4-40 | .375 | Stainless |

| 4-40 x 3/8in Phillips Panhead, Stainless | Machine Screw 4-40 x 3/8in Phillips Pan Head 18-8 Stainless | 4-40 | .375 | Stainless Cold-rolled Aluminum |

| 0MAS04400500PNP0100 | Machine Screw 4-40 x 1/2in Phillips Pan Head 18-8 Stainless | 4-40 | .500 | Stainless Cold-rolled Aluminum |

| 0MAS04400500PNP01BX | Machine Screw 4-40 x 1/2in Phillips Pan Head 18-8 Stainless Black Oxide | 4-40 | .500 | Stainless Cold-rolled Aluminum |

| 91772A115 | 91772A115 18-8 Stainless Steel Phillips Rounded Head Screw 4-40 Thread Size, 1in Long | 4-40 | 1.000 | Stainless Cold-rolled Aluminum |

| 91771A115 | Machine Screw 4-40 x 1in Phillips Flat Head 82° 18-8 Stainless | 4-40 | 1.000 | Stainless Cold-rolled Aluminum |

| 91771A148 | Machine Screw 6-32 x 1/2in Phillips Flat Head 82° 18-8 Stainless | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32 x 3/8in FlatHead Zinc 100º | Machine Screw 6-32 x 3/8in Phillips Flat Head 100° Steel Zinc | 6-32 | Stainless Cold-rolled Aluminum | |

| 93365A130 | Tapered Heat-Set Inserts for Plastic 6-32 Thread Size, 0.150in Installed Length, Brass | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8 FH Black 100 | Machine Screw 6-32 x 3/8in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8PAN PH SS | Machine Screw 6-32 x 3/8in Phillips Pan Head 18-8 Stainless | 6-32 | Stainless Cold-rolled Aluminum | |

| 93365A132 | Tapered Heat-Set Inserts for Plastic 6-32 Thread Size, 1/4in Installed Length, Brass | 6-32 | Stainless Cold-rolled Aluminum | |

| #6-32 Computer Case Fastener Thumb Screw | ONLYKXY #6-32 Computer Case Fastener Screws Black PC Computer Case Screw Hand Tighten Thumb Screws (10pcs) | 6-32 | Stainless Cold-rolled Aluminum | |

| 91475A020 | Mil Spec. Split Lock Washer No.6 18-8 Stainless (MS-35338-136) | 6-32 | Stainless Cold-rolled Aluminum | |

| 98032A436 | Mil. Spec. Cadmium-Plated Steel Flat Washer, Number 6 Screw Size, MS-27183-43, 0.156" ID | 6-32 | Stainless Cold-rolled Aluminum | |

| 91240A007 | Mil Spec. Hex Nut 6-32 18-8 Stainless (MS-35649-264) 5/16in Wide, 7/64in High | 6-32 | Stainless Cold-rolled Aluminum | |

| 91831A007 | Hex Nut Nylon Lock 6-32 18-8 Stainless, Size 5/16in Width, 11/64in Height | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8PAN PH SS B0 | Machine Screw 6-32 x 3/8in Phillips Pan Head 18-8 Stainless Black Oxide | 6-32 | Stainless Cold-rolled Aluminum | |

| MSPP0606 | Machine Screw 6-32 x 3/8in Phillips Pan Head Steel Zinc | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8FLT PH SS B0 | Machine Screw 6-32 x 3/8in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8FLT PH ST ZC | Machine Screw 6-32 x 3/8in Phillips Flat Head 82° Steel Zinc | 6-32 | Stainless Cold-rolled Aluminum | |

| 6-32X3/8FLT PH SS PS | Machine Screw 6-32 x 3/8in Phillips Flat Head 82° 18-8 Stainless | 6-32 | Stainless Cold-rolled Aluminum | |

| HN0632 | Hex Nut 6-32 Steel Zinc | 6-32 | Stainless Cold-rolled Aluminum | |

| HNS0632 | Hex Nut 6-32 18-8 Stainless | 6-32 | Stainless Cold-rolled Aluminum | |

| 96537A130 | Hex Nut 6-32 18-8 Stainless Black Oxide | 6-32 | Stainless Cold-rolled Aluminum | |

| 90272A143 | Machine Screw 6-32 x 3/16in Phillips Pan Head Steel Zinc | 6-32 | .187 | |

| 90273A143 - 45Drives | Machine Screw 6-32 x 3/16in Phillips Flat Head Undercut 82° Steel Zinc - 45Drives | 6-32 | .187 | |

| 91772A143 | Machine Screw 6-32 x 3/16in Phillips Pan Head 18-8 Stainless | 6-32 | .187 | Stainless Cold-rolled Aluminum |

| 97763A141 | Black-Oxide SS Button Head Socket Cap Screw 6-32 Thread, 1/4in Length | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 6-32 x 1/4 FlatHead 100° 18-8SS BlackOX | Machine Screw 6-32 x 1/4in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 0MAS06320250PNP01BX | Machine Screw 6-32 x 1/4in Phillips Pan Head 18-8 Stainless steel Black Oxide | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| MSPP0604 | Machine Screw 6-32 x 1/4in Phillips Pan Head Steel Zinc | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 6-32X1/4PAN PH SS | Machine Screw 6-32 x 1/4in Phillips Pan Head 18-8 Stainless | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 0MAS06320250FCP40ZR | Machine Screw 6-32 x 1/4in Phillips Flat Head 100° Steel Zinc | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 6-32X1/4FT1 PH SS PS | Machine Screw 6-32 x 1/4in Phillips Flat Head 100° 18-8 Stainless | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 6-32X1/4FLT PH ST B0 | Machine Screw 6-32 x 1/4in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 6-32X1/4FLT PH SS PS | Machine Screw 6-32 x 1/4in Phillips Flat Head 82° 18-8 Stainless | 6-32 | .250 | Stainless Cold-rolled Aluminum |

| 93085A145 | Machine Screw 6-32 x 5/16in Phillips Flat Head 100° 18-8 Stainless (MS24693-C25) | 6-32 | .312 | Stainless Cold-rolled Aluminum |

| 91259A162 | Alloy Steel Shoulder Screw 5/32in Diameter x 3/8in Long Shoulder, 6-32 Thread | 6-32 | .375 | |

| PSM6x3/8-PH-SS-TYB-BP | Thread Forming Screw No.6 x 3/8in Phillips Pan Head 18-8 Stainless Black Passivate | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| MS 51959-28B | Mil Spec. Machine Screw 6-32 x 3/8in Phillips FLAT HEAD 82DEG Stainless Steel Black (MS 51959-28B) | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| FSM6x3/8-PH-SS-TYB | Thread Forming Screw No.6 x 3/8in Phillips Flat Head 82° 18-8 Stainless | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| FSM6x3/8-PH-SS-TYB-BP | Thread Forming Screw No.6 x 3/8in Phillips Flat Head 82° 18-8 Stainless Black Passivate | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| FCMPS0606 | Machine Screw 6-32 x 3/8in Phillips Flat Head 100° 18-8 Stainless | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| PSM6x3/8-PH-SS-TYB | Thread Forming Screw No.6 x 3/8in Phillips Pan Head 18-8 Stainless | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| 97124A236 | Machine Screw 6-32 x 3/8in Phillips Flat Head 82° 2024 Aluminum | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| 91400A146 | Machine Screw 6-32 x 3/8in Phillips Pan Head 18-8 Stainless (MS 51957-28) | 6-32 | .375 | Stainless Cold-rolled Aluminum |

| 91772A149 | Machine Screw 6-32 x 7/16in Phillips Pan Head 18-8 Stainless | 6-32 | .437 | Stainless Cold-rolled Aluminum |

| 93085A148 | Machine Screw 6-32 x 1/2in Phillips Flat Head 100° 18-8 Stainless (MS24693-C28) | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| PSM6x1/2-PH-SS-TYB-BP | Thread Forming Screw No.6 x 1/2in Phillips Pan Head 18-8 Stainless Black Passivate | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| FSM6x1/2-PH-SS-TYB | Thread Forming Screw No.6 x 1/2in Phillips Flat Head 82° 18-8 Stainless | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| FSM6x1/2-PH-SS-TYB-BP | Thread Forming Screw No.6 x 1/2in Phillips Flat Head 82° 18-8 Black Passivate | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| PSM6x1/2-PH-SS-TYB | Thread Forming Screw No.6 x 1/2in Phillips Pan Head 18-8 Stainless | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| 0MAS06320500PNP0100 | Machine Screw 6-32 x 1/2in Phillips Pan Head 18-8 Stainless | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| 0MAS06320500PNP01BX | Machine Screw 6-32 x 1/2in Phillips Pan Head 18-8 Stainless Black Oxide | 6-32 | .500 | Stainless Cold-rolled Aluminum |

| 91772A151 | Machine Screw 6-32 x 3/4in Phillips Pan Head 18-8 Stainless | 6-32 | .750 | Stainless Cold-rolled Aluminum |

| 93085A151 | Machine Screw 6-32 x 3/4in Phillips Flat Head 100° 18-8 Stainless (MS24693-C30) | 6-32 | .750 | Stainless |

| 91771A153 | Machine Screw 6-32 x 1in Phillips Flat Head 82° 18-8 Stainless | 6-32 | 1.000 | Stainless Cold-rolled Aluminum |

| 90273A157 | Machine Screw 6-32 x 1-1/2in Phillips Flat Head 82° Steel Zinc | 6-32 | 1.500 | |

| MSPP0806 | Machine Screw 8-32 x 3/8in Phillips Pan Head Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| 8-32X3/8FLT PH SS B0 | Machine Screw 8-32 x 3/8in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 8-32 | Stainless Cold-rolled Aluminum | |

| 8-32 x 3/8in FlatHead Zinc 82° | Machine Screw 8-32 x 3/8in Phillips Flat Head 82° Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| 91831A009 | Hex Nut Nylon Lock 8-32 18-8 Stainless, Size 11/32in Width, 15/64in Height | 8-32 | Stainless Cold-rolled Aluminum | |

| FMSP0806 | Machine Screw 8-32 x 3/8in Phillips Flat Head 82° 18-8 Stainless | 8-32 | Stainless Cold-rolled Aluminum | |

| HN0832 | Hex Nut 8-32 Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| HN_8-32_18-8SS | Hex Nut 8-32 18-8 Stainless | 8-32 | Stainless Cold-rolled Aluminum | |

| 0NUT08320000MS001BX | Hex Nut 8-32 18-8 Stainless Black Oxide | 8-32 | Stainless Cold-rolled Aluminum | |

| 93181A009 | Hex Nut 8-32 6061 Aluminum | 8-32 | Stainless Cold-rolled Aluminum | |

| 8-32X1/4FLT PH SS B0 | Machine Screw 8-32 x 1/4in Phillips Flat Head 82° 18-8 Stainless Black Oxide | 8-32 | Stainless Cold-rolled Aluminum | |

| FMPP0804 | Machine Screw 8-32 x 1/4in Phillips Flat Head 82° Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| 8-32X1/4PAN PH ST ZC | Machine Screw 8-32 x 1/4in Phillips Pan Head Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| FCMP0806 | Machine Screw 8-32 x 3/8in Phillips Flat Head 100° Steel Zinc | 8-32 | Stainless Cold-rolled Aluminum | |

| 91475A025 | Mil Spec. Split Lock Washer No.8 18-8 Stainless (MS-35338-137) | 8-32 | Stainless Cold-rolled Aluminum | |

| 91240A009 | Mil Spec. Hex Nut 8-32 18-8 Stainless (MS-35649-284) 11/32in Wide, 1/8in High | 8-32 | Stainless Cold-rolled Aluminum | |

| 93365A140 | Tapered Heat-Set Inserts for Plastic 8-32 Thread Size, 0.185in Installed Length, Brass | 8-32 | Stainless Cold-rolled Aluminum | |

| 0MAS08320500PNP01BX | Machine Screw 8-32 x 1/2in Phillips Pan Head 18-8 Stainless Black Oxide | 8-32 | Stainless Cold-rolled Aluminum | |

| 93365A142 | Tapered Heat-Set Inserts for Plastic 8-32 Thread Size, 0.312in Installed Length, Brass | 8-32 | Stainless Cold-rolled Aluminum | |

| 91772A190 | Machine Screw 8-32 x 1/4in Phillips Pan Head 18-8 Stainless | 8-32 | .250 | Stainless Cold-rolled Aluminum |

| 0MAS08320250PNP40BR | Machine Screw 8-32 x 1/4in Phillips Pan Head Steel Black Oxide | 8-32 | .250 | Stainless Cold-rolled Aluminum |

| 8-32X1/4FT1 PH SS BO | Machine Screw 8-32 x 1/4in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 8-32 | .250 | Stainless Cold-rolled Aluminum |

| 96640A122 | Machine Screw 8-32 x 1/4in Phillips Flat Head Undercut 82° 18-8 Stainless Black Oxide | 8-32 | .250 | Stainless Cold-rolled Aluminum |

| 8-32X3/8PAN PH ST BZ | Machine Screw 8-32 x 3/8in Phillips Pan Head Steel Black Zinc | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 8-32X3/8PAN PH SS PS | Machine Screw 8-32 x 3/8in Phillips Pan Head 18-8 Stainless | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 97124A336 | Machine Screw 8-32 x 3/8in Phillips Flat Head 82° 2024 Aluminum | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 8-32 x 3/8 PanHead 18-8SS BlackOX | Machine Screw 8-32 x 3/8in Phillips Pan Head 18-8 Stainless Black Oxide | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| FCMPS0806 | Machine Screw 8-32 x 3/8in Phillips Flat Head 100° 18-8 Stainless | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 90825A814 | Machine Screw 8-32 x 3/8in Phillips Pan Head 18-8 Stainless (Sealing) | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 8-32X3/8FT1 PH SS B0 | Machine Screw 8-32 x 3/8in Phillips Flat Head 100° 18-8 Stainless Black Oxide | 8-32 | .375 | Stainless Cold-rolled Aluminum |

| 91400A194 | Mil Spec. Machine Screw 8-32 x 1/2in Phillips Pan Head 18-8 Stainless (MS-51957-45) | 8-32 | .500 | Stainless Cold-rolled Aluminum |

| 0MAS08320500PNP0100 | Machine Screw 8-32 x 1/2in Phillips Pan Head 18-8 Stainless | 8-32 | .500 | Stainless |

| 97763A178 | Socket Cap Screw 8-32 x 1/2in Button Head 18-8 Stainless Black Oxide (Fully Threaded) | 8-32 | .500 | Stainless Cold-rolled Aluminum |

| 91771A194 | Machine Screw 8-32 x 1/2in Phillips Flat Head 82° 18-8 Stainless | 8-32 | .500 | Stainless Cold-rolled Aluminum |

| 91771A199 | Machine Screw 8-32 x 1in Phillips Flat Head 82° 18-8 Stainless | 8-32 | 1.000 | Stainless Cold-rolled Aluminum |

| 91772A199 | 18-8 Stainless Steel Pan Head Phillips Machine Screw, 8-32 Thread, 1in Length | 8-32 | 1.000 | Stainless Cold-rolled Aluminum |

| 90273A203 | Machine Screw 8-32 x 1-1/2in Phillips Flat Head 82° Steel Zinc | 8-32 | 1.500 | Stainless Cold-rolled Aluminum |

| 10-24 x 3/8in PanHead Zinc | Machine Screw 10-24 x 3/8in Phillips Pan Head Steel Zinc | 10-24 | Stainless Cold-rolled Aluminum | |

| 10-24 x 3/8in FlatHead Zinc 82º | Machine Screw 10-24 x 3/8in Phillips Flat Head 82° Steel Zinc | 10-24 | Stainless Cold-rolled Aluminum | |

| HN_10-24_ST_ZI | Hex Nut 10-24 Steel Zinc | 10-24 | Stainless Cold-rolled Aluminum | |

| 93365A150 | Tapered Heat-Set Inserts for Plastic 10-24 Thread Size, 0.25in Installed Length, Brass | 10-24 | Stainless Cold-rolled Aluminum | |

| 93365A152 | Tapered Heat-Set Inserts for Plastic 10-24 Thread Size, 3/8in Installed Length, Brass | 10-24 | Stainless Cold-rolled Aluminum | |

| MSPP1120 | Machine Screw 10-32 x 1 1/4in Phillips Pan Head Steel Zinc | 10-32 | Stainless Cold-rolled Aluminum | |

| 10-32X3/8PAN PH ST ZC | Machine Screw 10-32 x 3/8in Phillips Pan Head Steel Zinc | 10-32 | Stainless Cold-rolled Aluminum | |

| 10-32X3/8PAN PH SS PS | Machine Screw 10-32 x 3/8in Phillips Pan Head 18-8 Stainless | 10-32 | Stainless Cold-rolled Aluminum | |

| 10-32X3/8FLT PH SS PS | Machine Screw 10-32 x 3/8in Phillips Flat Head 82° 18-8 Stainless | 10-32 | Stainless Cold-rolled Aluminum | |

| 10-32X3/8FLT PH ST ZC | Machine Screw 10-32 x 3/8in Phillips Flat Head 82° Steel Zinc | 10-32 | Stainless Cold-rolled Aluminum | |

| HNS1032 | Hex Nut 10-32 18-8 Stainless | 10-32 | Stainless Cold-rolled Aluminum | |

| 90257A411 | Hex Nut 10-32 316 Stainless | 10-32 | Stainless Cold-rolled Aluminum | |

| 92147A430 | Split Lock Washer No.10 316 Stainless (pack 100) | 10-32 | Stainless Cold-rolled Aluminum | |

| 93365A154 | Tapered Heat-Set Inserts for Plastic 10-32 Thread Size, 0.25in Installed Length, Brass | 10-32 | Stainless Cold-rolled Aluminum | |

| 93365A156 | Tapered Heat-Set Inserts for Plastic 10-32 Thread Size, 3/8in Installed Length, Brass | 10-32 | Stainless Cold-rolled Aluminum | |

| 91771A825 | Machine Screw 10-32 x 1/4in Phillips Flat Head Undercut 82° 18-8 Stainless | 10-32 | .250 | Stainless Cold-rolled Aluminum |

| 0NUT10320000MS040ZR | Hex Nut 10-32 Steel Zinc | 10-32 | .250 | Stainless Cold-rolled Aluminum |

| 91251A338 | Socket Cap Screw 10-32 x 1/4in Socket Head Steel Black Oxide (Fully Threaded) | 10-32 | .250 | Stainless Cold-rolled Aluminum |

| 91772A825 | 18-8 SS Pan Head Phillips Machine Screw 10-32 Thread, 1/4" Length | 10-32 | .250 | Stainless Cold-rolled Aluminum |

| 91249A258 | Black-Oxide Fnsh Pan Head Phil Machine Screw 18-8 SS, 10-32 Thread, 1/4in Length | 10-32 | .250 | Stainless Cold-rolled Aluminum |

| 93085A823 | Mil Spec. Machine Screw 10-32 x 5/16in Phillips Flat Head 100° 18-8 Stainless (MS-24693-C269) | 10-32 | .312 | Stainless Cold-rolled Aluminum |

| 18-8 10-32 x 5/16 FLT PH MS | Machine Screw 10-32 x 5/16in Phillips Flat Head 82° 18-8 Stainless | 10-32 | .312 | Stainless Cold-rolled Aluminum |

| 91249A260 | Black-Oxide Fnsh Pan Head Phil Machine Screw 18-8 SS, 10-32 Thread, 0.375in Length | 10-32 | .375 | Stainless Cold-rolled Aluminum |

| 91735A827 | Machine Screw 10-32 x 3/8in Phillips Pan Head 316 Stainless | 10-32 | .375 | Stainless Cold-rolled Aluminum |

| 96640A141 | 18-8 SS Flat Head Phillips Machine Screw Black Oxide Finish, 10-32 Thread, 3/8in Length, 82 degree | 10-32 | .375 | Stainless Cold-rolled Aluminum |

| 10-32 x 3/8in Flat Head SS 100º | Machine Screw 10-32 x 3/8in Phillips Flat Head 100° 18-8 Stainless | 10-32 | .375 | Stainless Cold-rolled Aluminum |

| 91771A829 | Machine Screw 10-32 x 1/2in Phillips Flat Head 82° 18-8 Stainless | 10-32 | .500 | Stainless Cold-rolled Aluminum |

| 10-32 x 1/2in PanHead Stainless (18-8) | Machine Screw 10-32 x 1/2in Phillips Pan Head 18-8 Stainless | 10-32 | .500 | Stainless Cold-rolled Aluminum |

| 97763A232 | Socket Cap Screw 10-32 x 1/2in Button Head 18-8 Stainless Black Oxide (Fully Threaded) | 10-32 | .500 | Stainless Cold-rolled Aluminum |

| 91735A830 | Machine Screw 10-32 x 5/8in Phillips Pan Head 316 Stainless | 10-32 | .625 | Stainless Cold-rolled Aluminum |

| 91772A833 | Passivated 18-8 Stainless Steel Pan Head Phillips Screw 10-32 Thread, 1" Long | 10-32 | 1.000 | Stainless Cold-rolled Aluminum |

| 91771A833 | Machine Screw 10-32 x 1in Phillips Flat Head 82° 18-8 Stainless | 10-32 | 1.000 | Stainless Cold-rolled Aluminum |

| 91772A835 | Machine Screw 10-32 x 1 1/4in Phillips Pan Head 18-8 Stainless | 10-32 | 1.250 | Stainless Cold-rolled Aluminum |

| 93575A029 | Wing Nut 1/4-20 316 Stainless | 1/4-20 | Stainless Cold-rolled Aluminum | |

| 91849A029 | Hex Nut 1/4-20 18-8 Stainless (Extra-Wide - 1/2in Wide, 15/64in High) | 1/4-20 | Stainless Cold-rolled Aluminum | |

| 95462A029 | Hex Nut 1/4-20 Steel Zinc | 1/4-20 | Stainless Cold-rolled Aluminum | |

| 93365A160 | Tapered Heat-Set Inserts for Plastic 1/4-20 Thread Size, 0.3in Installed Length, Brass | 1/4-20 | Stainless Cold-rolled Aluminum | |

| 93365A162 | Tapered Heat-Set Inserts for Plastic 1/4-20 Thread Size, 1/2in Installed Length, Brass | 1/4-20 | Stainless Cold-rolled Aluminum | |

| 95479A111 | Hex Nut 1/4-20 Steel Black Oxide | 1/4-20 | .375 | Stainless Cold-rolled Aluminum |

| 91772A537 | Machine Screw 1/4-20 x 1/2in Phillips Pan Head 18-8 Stainless | 1/4-20 | .500 | Stainless Cold-rolled Aluminum |

| 92185A542 | Socket Cap Screw 1/4-20 x 1in Socket Head 316 Stainless (Fully Threaded) | 1/4-20 | 1.000 | Stainless Cold-rolled Aluminum |

| 95479A118 | Hex Nut 3/8-16 Steel Black Oxide | 3/8-16 | Stainless Cold-rolled Aluminum | |

| 94804A030 | Hex Nut 5/16-18 316 Stainless | 5/16-18 | Stainless Cold-rolled Aluminum | |

| 92196A578 | Socket Cap Screw 5/16-18 x 1/2in Socket Head 18-8 Stainless (Fully Threaded) | 5/16-18 | .500 | Stainless Cold-rolled Aluminum |

| 94180A321 | Tapered Heat-Set Inserts for Plastic Brass, M2.5 x 0.45 mm Thread Size, 3.4 mm Installed Length | m2.5 | Stainless Cold-rolled Aluminum | |

| 9200A104 | Machine Screw M2.5-.45 x 6mm Phillips Pan Head 18-8 Stainless | m2.5 | 6 mm | |

| 94180A333 | Tapered Heat-Set Inserts for Plastic Brass, M3 x 0.50 mm Thread Size, 6.400 mm Installed Length | m3 | Stainless Cold-rolled Aluminum | |

| M3HEX ST SS | Hex Nut M3-.5 18-8 Stainless | m3 | Stainless Cold-rolled Aluminum | |

| MMASM003M004PNP0100 | Machine Screw M3-.5 x 4mm Phillips Pan Head 18-8 Stainless | m3 | .250 | Stainless Cold-rolled Aluminum |

| M3HEX ST ZC | Hex Nut M3-.5 Steel Zinc | m3 | .250 | Stainless Cold-rolled Aluminum |

| 92010A122 | Machine Screw M3-.5 x 12mm Phillips Flat Head 90° 18-8 Stainless | m3 | 12 mm | Stainless Cold-rolled Aluminum |

| M3X12MMPAN PH SS PS | Machine Screw M3-.5 x 12mm Phillips Pan Head 18-8 Stainless | m3 | 12 mm | Stainless Cold-rolled Aluminum |

| 92000A130 | 18-8 Stainless Steel Metric Pan Head Phillips Machine Screw, M3 Size, 25mm Length, .5mm Pitch | m3 | 25 mm | Stainless Cold-rolled Aluminum |

| 92010A130 | Machine Screw M3-.5 x 25mm Phillips Flat Head 90° 18-8 Stainless | m3 | 25 mm | Stainless Cold-rolled Aluminum |

| M3X4MMFT9 | Machine Screw M3-.5 x 4mm Phillips Flat Head 90° 18-8 Stainless | m3 | 4 mm | Stainless Cold-rolled Aluminum |

| 91698A301 | Machine Screw M3-.5 x 5mm Phillips Flat Head 90° 18-8 Stainless Black Oxide | m3 | 5 mm | Stainless Cold-rolled Aluminum |

| M3X6MMPAN PH ST BZ | M3 x 6mm PanHead, Steel, Black Zinc | m3 | 6 mm | Stainless Cold-rolled Aluminum |

| M3X6MMPAN PH SS PS | Machine Screw M3-.5 x 6mm Phillips Pan Head 18-8 Stainless | m3 | 6 mm | Stainless Cold-rolled Aluminum |

| MS_M3-.5_6mm_PPH_18-8SS_BO | Machine screw, Phillips pan head, M3x.5, 6mm length, 18-8 Stainless, Black Oxide | m3 | 6 mm | Stainless Cold-rolled Aluminum |

| 92095A179 | Metric 18-8 SS Button Head Socket Cap Screw M3 Size, 6 mm Length, .5 mm Pitch | m3 | 6 mm | Stainless Cold-rolled Aluminum |

| 95836A205 | Metric Pan Head Phillips Machine Screw, Black-Oxide 18-8 Stainless Steel, M3 Size, 6MM Length, .5MM Pitch, packs of 50 | m3 | 6 mm | Stainless Cold-rolled Aluminum |

| MS_M3-.5_8mm_PFH_90_18-8SS | Machine Screw M3-.5 x 8mm Phillips Flat Head 90° 18-8 Stainless | m3 | 8 mm | Stainless Cold-rolled Aluminum |

| M3X8MMPAN PH SS PS | Machine Screw M3-.5 x 8mm Phillips Pan Head 18-8 Stainless | m3 | 8 mm | Stainless Cold-rolled Aluminum |

| M3 x 8mm PanHead 18-8 Stainless, Black | Machine Screw M3-.5 x 8mm Phillips Pan Head 18-8 Stainless Black Oxide | m3 | 8 mm | Stainless Cold-rolled Aluminum |

| 91698A304 | Machine Screw M3-.5 x 8mm Phillips Flat Head 90° 18-8 Stainless Black Oxide | m3 | 8 mm | Stainless Cold-rolled Aluminum |

| 94180A353 | Tapered Heat-Set Inserts for Plastic Brass, M4 x 0.70 mm Thread Size, 7.900 mm Installed Length | m4 | Stainless Cold-rolled Aluminum | |

| M4HEX ST ZC | Hex Nut M4-.7 Steel Zinc | m4 | Stainless Cold-rolled Aluminum | |

| M4HEX ST SS | Hex Nut M4-.7 18-8 Stainless | m4 | Stainless Cold-rolled Aluminum | |

| 92010A222 | Machine Screw M4-.7 x 12mm Phillips Flat Head 90° 18-8 Stainless | m4 | 12 mm | Stainless Cold-rolled Aluminum |

| 92125A192 | 18-8 Stainless Steel Hex Drive Flat Head Screw M4 x 0.7 mm Thread, 12 mm Long | m4 | 12 mm | Stainless Cold-rolled Aluminum |

| 92000A222 | 18-8 Stainless Steel Metric Pan Head Phillips Machine Screw, M4 Size, 12mm Length, .7mm Pitch | m4 | 12 mm | Stainless Cold-rolled Aluminum |

| 92010A230 | Machine Screw M4-.7 x 25mm Phillips Flat Head 90° 18-8 Stainless | m4 | 25 mm | Stainless Cold-rolled Aluminum |

| 92000A230 | 18-8 Stainless Steel Phillips Rounded Head Screws, M4 x 0.7 mm Thread, 25 mm Long | m4 | 25 mm | Stainless Cold-rolled Aluminum |

| M4X5MMPAN PH SS PS | Machine Screw M4-.7 x 5mm Phillips Pan Head 18-8 Stainless | m4 | 5 mm | Stainless Cold-rolled Aluminum |

| M4X6MMPAN PH ST ZC | Machine Screw M4-.7 x 6mm Phillips Pan Head Steel Zinc | m4 | 6 mm | Stainless Cold-rolled Aluminum |

| M4X6MMFT9 PH ST ZC | Machine Screw M4-.7 x 6mm Phillips Flat Head 90° Steel Zinc | m4 | 6 mm | Stainless Cold-rolled Aluminum |

| M4X6MMPAN PH ST ZB | Machine Screw M4-.7 x 6mm Phillips Pan Head Steel Black Oxide | m4 | 6 mm | Stainless Cold-rolled Aluminum |

| Machine screw, Phillips pan head, M4-.7, 6mm length, Stainless, Black Oxide | Machine Screw M4-.7 x 6mm Phillips Pan Head 18-8 Stainless Black Oxide | m4 | 6 mm | Stainless Cold-rolled Aluminum |

| M4X8MMFT9 PH ST ZC | Machine Screw M4-.7 x 8mm Phillips Flat Head 90° Steel Zinc | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| M4X8MMFT9 PH SS PS | Machine Screw M4-.7 x 8mm Phillips Flat Head 90° 18-8 Stainless | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| MMASM004M008PNP01BX | Machine Screw M4-.7 x 8mm Phillips Pan Head 18-8 Stainless Black Oxide | m4 | 8 mm | |

| 94500A226 | Type 316 Stainless Steel Button-Head Socket Cap Screw, M4 Size, 8 mm Long, 0.7 mm Pitch | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| 92125A188 | 18-8 Stainless Steel Hex Drive Flat Head Screw M4 x 0.7 mm Thread, 8 mm Long | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| 92000A218 | Machine Screw M4-.7 x 8mm Phillips Pan Head 18-8 Stainless | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| 91698A426 | Machine Screw M4-.7 x 8mm Phillips Flat Head 90° 18-8 Stainless Black Oxide | m4 | 8 mm | Stainless Cold-rolled Aluminum |

| 94180A363 | Tapered Heat-Set Inserts for Plastic Brass, M5 x 0.80 mm Thread Size, 11.100 mm Installed Length | m5 | Stainless Cold-rolled Aluminum | |

| 91828A241 | Hex Nut M5-.8 18-8 Stainless | m5 | Stainless Cold-rolled Aluminum | |

| 92000A320 | Machine Screw M5-.8 x 10mm Phillips Pan Head 18-8 Stainless | m5 | 10 mm | Stainless Cold-rolled Aluminum |

| 92010A320 | Machine Screw M5-.8 x 10mm Phillips Flat Head 90° 18-8 Stainless | m5 | 10 mm | Stainless Cold-rolled Aluminum |

| M5HEX ST ZC | Hex Nut M5-.8 Steel Zinc | m5 | 8 mm | Stainless Cold-rolled Aluminum |

| 94180A373 | Tapered Heat-Set Inserts for Plastic Brass, M6 x 1 mm Thread Size, 12.700 mm Installed Length | m6 | Stainless Cold-rolled Aluminum | |

| M6HEX ST ZC | Hex Nut M6-1 Steel Zinc | m6 | Stainless Cold-rolled Aluminum | |

| M6 x 10mm FlatHead Stainless 90º | Machine Screw M6-1 x 10mm Phillips Flat Head 90° 18-8 Stainless | m6 | 10 mm | Stainless Cold-rolled Aluminum |

| 92000A424 | Passivated 18-8 Stainless Steel Pan Head Phillips Screws M6 x 1mm Thread, 12mm Long | m6 | 12 mm | Stainless Cold-rolled Aluminum |

| 92010A424 | Passivated 18-8 Stainless Steel Phillips Flat Head Screw M6 x 1 mm Thread, 12 mm Long | m6 | 12 mm | Stainless Cold-rolled Aluminum |

| 92000A430 | Passivated 18-8 Stainless Steel Pan Head Phillips Screws M6 x 1mm Thread, 25mm Long | m6 | 25 mm | Stainless Cold-rolled Aluminum |

| 92010A430 | Passivated 18-8 Stainless Steel Phillips Flat Head Screw M6 x 1 mm Thread, 25 mm Long | m6 | 25 mm | Stainless Cold-rolled Aluminum |

| 94180A386 | Tapered Heat-Set Inserts for Plastic Brass, M8 x 1.25 mm Thread Size, 14.300 mm Installed Length | m8 | Stainless Cold-rolled Aluminum | |

| 94180A387 | Tapered Heat-Set Inserts for Plastic Brass, M10 x 1.50 mm Thread Size, 15.88 mm Installed Length | m10 | Stainless Cold-rolled Aluminum | |

| 91475A391 | Mil. Spec. Split Lock Washers Black Oxide 316 Stainless Steel, Number 10 Screw Size, MS35338 | Stainless Cold-rolled Aluminum | ||

| 93181A003 | Hex Nut 4-40 6061 Aluminum | Stainless Cold-rolled Aluminum | ||

| 94407A100 | 18-8 Stainless Steel Nylon-Insert Locknut, Black-Oxide, 4-40 Thread Size | Stainless Cold-rolled Aluminum | ||

| 98019A314 | Mil Spec. Flat Washer No.6 18-8 Stainless (MS-15795-805) ID.156in x OD.312 | Stainless Cold-rolled Aluminum | ||

| MILSMS35338-136 | WASHER, SPRING-LOCK # 6 REGULAR (MEDIUM) SERIES, CRES MS35338-136 | Stainless Cold-rolled Aluminum | ||

| 98019A325 | MS15795-807, WASHER No.8, .38inOD, .19inID, .04-.07inTHK | Stainless Cold-rolled Aluminum | ||

| 90107A030 | Type 316 Stainless Steel Flat Washer, 5/16" Screw Size, 0.344" ID, 0.750" OD | Stainless Cold-rolled Aluminum | ||

| FASTENER TBD | FASTENER TBD | Stainless | ||

| #8 x 1-inch Router Screw | Paulin #8 x 1-inch Flat Head Square Drive Zinc Plated Steel Particle Board Screws - 100pcs | Stainless Cold-rolled Aluminum | ||

| Thumb_Screw_001 | Computer PC Case Black Zinc Plated Knurled Phillips Head Thumb Screw 6#-32 , 40 pcs | Stainless Cold-rolled Aluminum | ||

| 90130A011 | EPDM Rubber Washer NO. 10 Screw Size, 3/8" OD, .093" Thick | Stainless Cold-rolled Aluminum | ||

| 95635A537 | Button Head Hex Drive Screw 1/4-20 x 1/2in 18-8 Stainless (Security style Pin in) (Fully Threaded) | Stainless Cold-rolled Aluminum | ||

| HEX_NUT_GENERIC_STANDARD | HEX_NUT_GENERIC_STANDARD | Stainless Cold-rolled Aluminum | ||

| HEX_NUT_GENERIC_METRIC | HEX_NUT_GENERIC_METRIC | Stainless Cold-rolled Aluminum | ||

| MACHINE_SCREW_GENERIC_METRIC | MACHINE_SCREW_GENERIC_METRIC | Stainless Cold-rolled Aluminum | ||

| 95836A253 | Machine Screw M2.5-.45 x 6mm Phillips Pan Head 18-8 Stainless BO | Stainless Cold-rolled Aluminum | ||

| 92147A029 | Split Lock Washer Screw Size 1/4in 316 Stainless | Stainless Cold-rolled Aluminum | ||

| MACHINE_SCREW_GENERIC_STANDARD | MACHINE_SCREW_GENERIC_STANDARD | Stainless Cold-rolled Aluminum | ||

| 91755A200 | Nylon Self-Retaining Washer, Number 2/M2 Screw Size, 13/64in OD, .02in-.04in Thick | Stainless Cold-rolled Aluminum | ||

| 91475A018 | Mil Spec. Split Lock Washer No.4 18-8 Stainless (MS-35338-135) | Stainless Cold-rolled Aluminum | ||

| 98032A425 | Mil. Spec. Cadmium-Plated Steel Flat Washer, Number 4 Screw Size, MS-27183-4, 0.125" ID | Stainless Cold-rolled Aluminum | ||

| 98032A514 | Mil. Spec. Cadmium-Plated Steel Flat Washer, 3/8" Screw Size, MS-27183-14, 0.406" ID | Stainless Cold-rolled Aluminum |